When manufacturing circuit boards, PCB thickness is a crucial factor that affects performance and production. Different types of thicknesses should be chosen according to the requirements of circuit board design and functionality. As technology develops and circuits become more complex, there are more thickness options. Here is an ultimate guide to help you gain insight into what factors affect PCB thickness.

What Is Standard PCB Thickness?

It is the thickness of the finished board. The circuit board thickness mainly depends on factors like the number of layers, copper layer thickness, substrate, etc. The 1.6mm PCB thickness is an industry standard. This thickness is widely regarded as the industry standard because it meets the requirements of most consumer electronics, offering a balance between strength, weight, and ease of assembly.

- The 1.6mm thick PCB achieves an ideal balance between mechanical performance and weight.

- The standard board thickness can assemble most through-hole components. The components leads are sufficiently lengthy to go through the board. If the board is thicker, the leads may not be long enough.

- The 1.6mm PCB board thickness makes production simple. A circuit board of this thickness has enough strength to prevent breakage during assembly without being too thick to make manufacturing more difficult. PCBs that are too thick will increase drilling time and require longer drill bits. Boards that are too thin are prone to deformation or damage during operation.

Key Factors Impacting the Thickness of the Circuit Board

The choice of the appropriate PCB thickness must be determined given a variety of factors. Let’s explore these impacting factors in more detail.

Weight and Flexibility

Thinner PCBs have the advantages of lightweight and high flexibility and are particularly suitable for flexible circuit designs that require bending and deformation. These PCBs have low mechanical strength and are prone to breakage. Thicker PCBs provide better stability and are suitable for applications with higher dependability needs. They also bring problems like increased weight and space occupation, which will limit their use in portable devices or space-constrained applications.

Copper Thickness

Copper thickness and weight affect the current it can carry and the ability to dissipate heat. In high-power devices, thicker copper layers are frequently needed to enhance heat dissipation and conductivity. This will also increase the overall PCB thickness accordingly.

Substrate Thickness

PCB substrates are usually made of materials like FR4 and polyimide. The circuit board’s mechanical strength is significantly impacted by its thickness and material choice.

Prepreg Thickness

Prepreg is a composite material composed of glass fiber and resin adhesive. In the PCB manufacturing process, it is sandwiched between copper layers and pressed under heat to form a laminate. The prepreg thickness needs to be determined by the total PCB thickness.

Number of Layers

PCB thickness is closely related to the number of layers. The standard PCB thickness is about 1.6mm. The more copper layers a circuit has, the thicker it is. The number of layers needs to be determined by the actual functional requirements when designing. If more layers are required, consider increasing the overall thickness.

Via Type

The application of vias makes PCB design more compact, and its type and density will directly affect the thickness of the circuit board. There are many kinds of vias, including through via, buried via, micro via, blind via, etc. Micro vias are suitable for thinner circuit boards because they have low thickness requirements and can achieve high-density connections.

Signal Type

The kind of signals conveyed on a PCB influences the thickness and selection of board materials. Wider traces and thicker copper layers are necessary for processing high-power signals in order to enhance current carrying capacity and lower resistance.

Working Environments

In harsh environments (such as high temperatures or highly corrosive environments), PCB performance is affected not only by thickness but also by material selection and surface treatment. Thicker PCBs may provide better mechanical stability.

How Does PCB Thickness Influence PCB Performance?

PCB thickness affects the overall performance of the printed circuit board. Choosing the right PCB thickness will allow the circuit board to perform at its best.

Thermal Management

PCB thickness affects the board’s thermal management capabilities. Thicker boards generally dissipate heat more effectively, and their thicker copper layers enhance thermal conductivity, allowing heat to be more evenly distributed throughout the board. Good heat dissipation is especially important in high-power or compact applications. It effectively prevents overheating of the board and components, ensuring stable system operation and extending the life of components.

Signal Integrity

PCB thickness affects the impedance control of the traces, which in turn affects signal integrity. Thicker PCBs help better control impedance, reduce signal reflections and crosstalk, and thus ensure accurate transmission of high-speed signals.

Mechanical Strength

PCB thickness affects the mechanical strength of the board, which is particularly important for devices that need to withstand physical stress or vibration. Thicker PCBs are more robust and can effectively resist bending or warping, reducing the risk of component and solder joint damage, and are suitable for harsh environments. Thin PCBs may crack under physical stress such as vibration, causing device failure. Increasing thickness also brings challenges of increased weight and reduced flexibility, which need to be balanced according to the specific mechanical requirements of the application.

Electrical Performance

PCB thickness has an important impact on electrical performance, including signal integrity, EMI shielding, current capacity, etc. Increasing thickness can help improve EMI shielding. In multi-layer PCBs, the thickness and arrangement of the layers will affect the layout of the power layer and the ground layer, which will directly affect the electrical performance. It is crucial to properly optimize the PCB thickness to achieve ideal electrical characteristics.

How Does the Thickness of PCB Affect the Manufacturing Process?

We also need to pay attention to the impact of PCB thickness on the manufacturing process. It directly affects multiple key manufacturing processes.

Drilling Equipment Limitations

Thicker PCBs face more challenges during the drilling process. To avoid damaging the board, thicker boards require more precise drilling control, and the depth and diameter of the holes must be precisely mastered.

Lamination Complexity

The thicker the PCB, the more complex the lamination process will be. The lamination process requires laminating multiple layers of copper and insulating materials under high temperatures and pressures into a complete circuit board. For thicker PCBs, greater pressure and longer lamination times are usually required to ensure even bonding between the layers. This increased pressure and time also brings potential risks that can lead to warping or delamination of the material. Accurate control of lamination parameters is critical to avoid these defects and ensure board quality.

Copper Etching

On thicker PCBs, the copper etching process becomes more complicated. For thicker copper layers, the etching process may require a longer time and stronger chemicals to remove excess copper. Etching time that is too long or chemicals that are too strong may result in under-etching or over-etching. It can affect the accuracy of the circuit pattern and even the overall quality of the circuit board.

Assembly Process

The installation of larger components (such as connectors and heat sinks) has specific requirements for PCB thickness and requires sufficient support to avoid deformation. PCB thickness will also affect the choice of soldering technique. Thicker circuit boards often require adjustment of thermal parameters and soldering materials when soldering to ensure good connection quality.

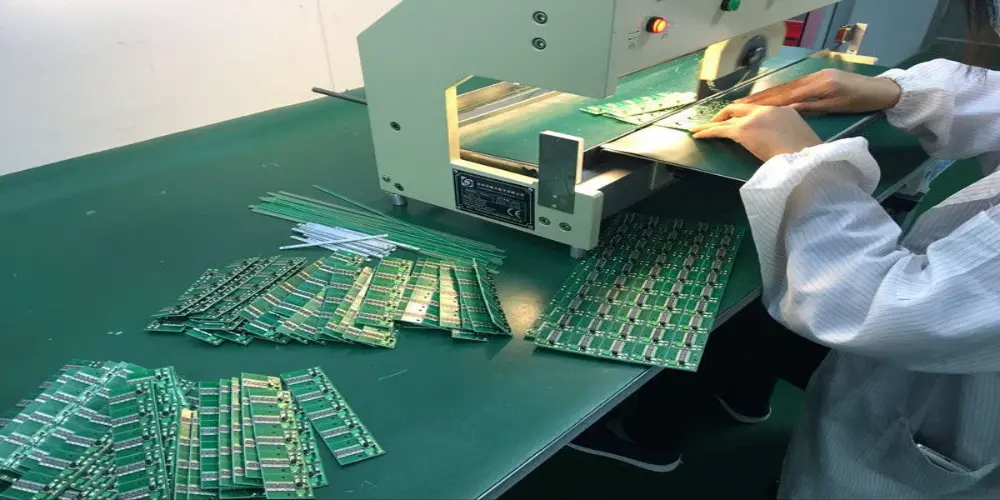

Depanelization Techniques

Larger panels often contain multiple boards that manufacturers separate into individual circuit boards. The thickness of the PCB influences the debonding methods that can be used. Thicker PCBs may require more aggressive debonding techniques, like routing or sawing. Thinner PCBs can be separated by scribing or laser cutting. Choosing the appropriate debonding method can prevent damage during the separation process.

How to Choose the Appropriate PCB Thickness?

PCB thickness selection requires consideration of multiple key factors, including the weight and flexibility of the board, space constraints, component installation requirements, electrical performance, etc. It is necessary to make a trade-off based on the specific application scenario to achieve the best performance. There are multiple PCB thickness options for different application scenarios. Here, PCBs are categorized based on thickness and given a simple for their application in detail. Understanding these ranges helps determine the most suitable board thickness for specific design requirements.

| Type of PCB | Thickness Range | Applications |

| Thin PCB | 0.4-1.0mm | Space-constrained applications |

| Thicker PCB | 1.6-2.4mm | Industrial applications |

| Extremely thick PCB | Above 2.4mm | Infrastructure and specialized equipment |

Thin PCB

Thin PCB thickness ranges from 0.4mm to 1.0mm. Thin PCBs are particularly suitable for space-constrained applications, like portable electronic devices, and wearable products. Thin PCB can achieve a smaller and thinner product design and reduce the overall weight.

Thicker PCB

Thicker PCB thickness ranges from 1.6mm to 2.4mm. Thicker PCBs are particularly suitable for industrial applications and rugged consumer devices because they have greater mechanical strength and durability than thin boards. This property enables them to better withstand mechanical shocks and be more durable.

Extremely Thick PCB

Extremely Thick PCB thickness is above 2.4mm. Ultra-thick PCBs are mainly used in critical infrastructure and specialized equipment such as server backplanes, telecommunication equipment, and large test boards. These PCBs need to reliably carry a large number of high-power components. The circuit boards are designed to be more robust and have excellent thermal management capabilities.

Final Words

Selecting the right PCB thickness is critical to guarantee circuit board manufacturability and optimal performance. There are a variety of thickness options to meet specific application requirements. Designers can choose the most appropriate PCB thickness for their project by carefully considering factors like thermal management, signal integrity, mechanical strength, and manufacturing constraints.