Have you ever wondered why a small electronic device can perform complex tasks and provide powerful performance? It’s all thanks to PCBA, which groups electronic components together on a circuit board to increase its efficiency and compactness. We have seen green boards in electronic devices, usually assembled, called PCBAs. They are an essential component of contemporary electrical equipment. Let us read this article in detail to learn more about PCBA.

What Is a PCBA?

PCBA is called Printed Circuit Board Assembly. It refers to a complete circuit board with all required electronic components mounted on it. This can also describe the process of components assembled on the PCB board. Then the board can be used in electronic devices and applications.

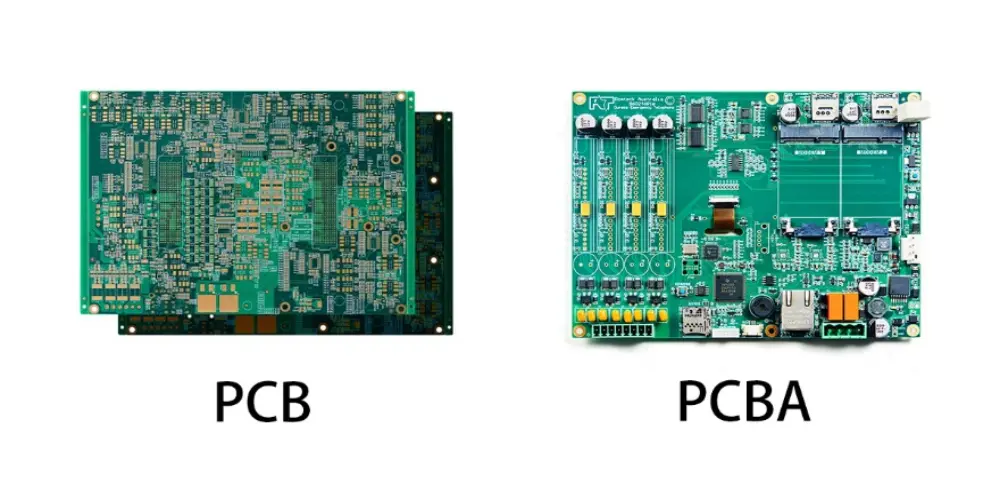

PCBA vs PCB: What Is the Difference?

A PCB (Printed Circuit Board) is an insulating board with conductive copper traces etched into its surface. These copper traces can connect electronic components like diodes and transistors. There are no electronic components installed on this blank board.

A PCBA (Printed Circuit Board Assembly) is a circuit board that has all required electronic components soldered to it to form a complete circuit. It is a complete circuit board ready to use in electronic devices.

Generally speaking, the principal role of PCB is to provide an essential foundation for placing and connecting various electronic components. Before manufacturing PCBA, the PCB is the basic board that must be manufactured first.

What Are the PCBA Components?

There are two types of components on the PCB board: active and passive components. Active components require a power supply to work, such as transistors and diodes. Passive components don’t need to, such as inductors, capacitors, and resistors. When choosing components, we need to consider the price, size, and, performance.

PCBA Manufacturing Process: Step-by-Step Guide

Step 1: Start With Preparation

It is required that the blank printed circuit board should be cleaned and inspected in a way before it is taken through the process of having components placed on it.

Step 2:Paste Stenciling

Solder paste is then applied to the specific region of the PCB to facilitate its melting and create an electrical connection to link the PCB and the component. It is usually not implemented with THT (Through Hole Technology), but it is needed in SMT (Surface-mount Technology).

Step 3: Component Placement

Check that all the components are well placed on the PCB board to match with the required standards. This can be done automatically by the machine or may be done by hand.

Step 4: Reflow Soldering

All the components have to be placed on the PCB board, then the PCB undergoes reflow soldering, and the solder paste is melted and re-solidified. There is an electrical connection between the board and the components.

Step 5: Inspect PCBA

The PCBA will be inspected to guarantee that electronic components are well-soldered and positioned correctly. It can be visually inspected by hand, using an X-ray, or with an automated optical inspection (AOI) system.

Step 6: Insert the Through-hole Component

If through-hole components are implemented in the assembly process then through-hole components are inserted either by human or through a machine at this stage.

Step 7: Wave Soldering

Solder the inserted through-hole components using a wave soldering machine to wet the leads and make good solder joints.

Step 8: Final Test and Clean

Cleaning of the PCBA is done to eliminate additional solder and other residues from the board. After this, the finished product is inspected to ensure that it has reached the required standard and is functional.

Common PCB Assembly Methods

Let’s take a deeper understanding of the three common methods below.

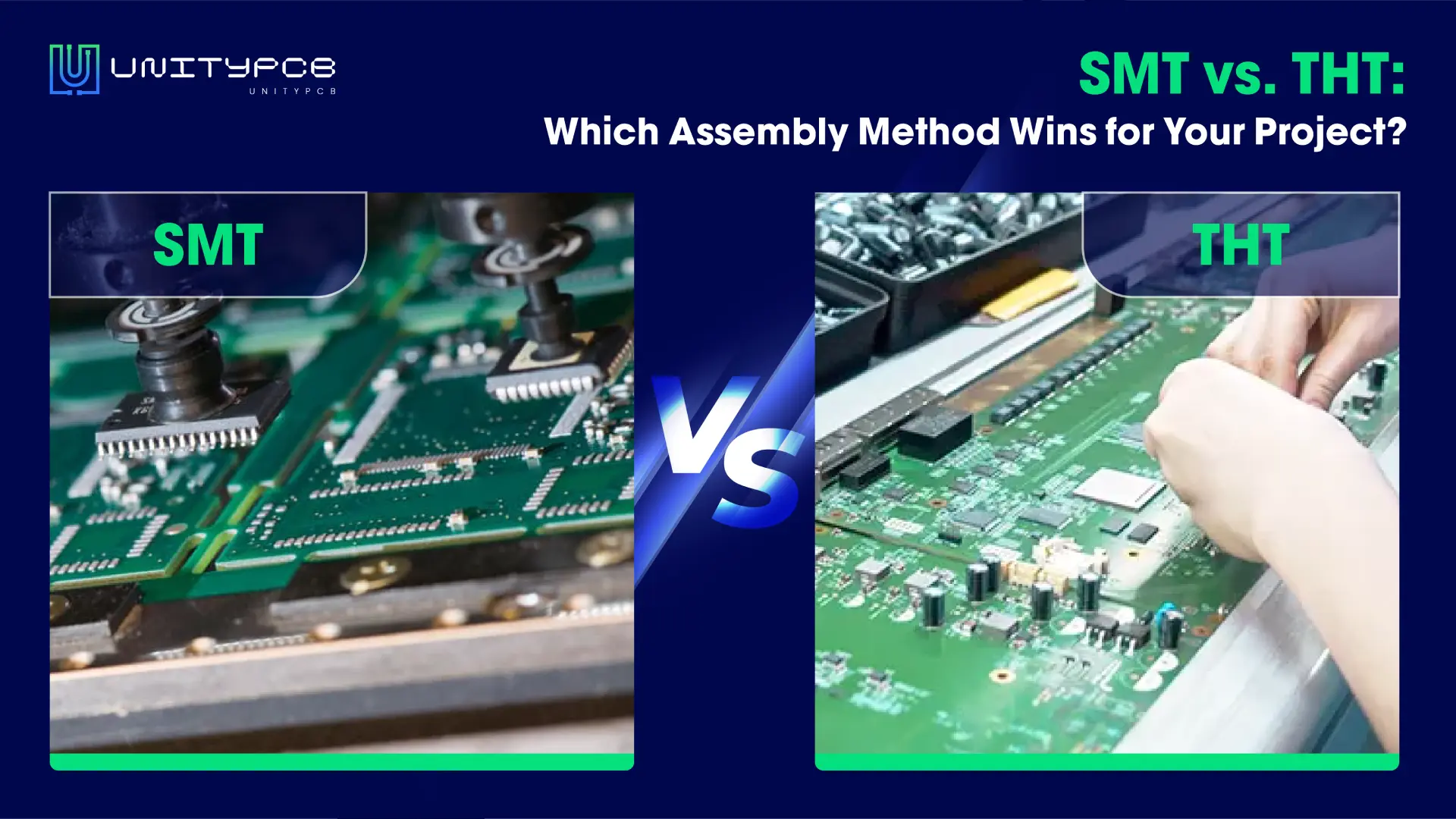

Surface-mount Technology (SMT)

It mounts components directly to the PCB surface without the requirement for through-holes. SMT has achieved automated production, labor cost savings, and production effectiveness. Wearables, tablets, and smartphones highly rely on this technology.

Through-hole Technology (THT)

Through-hole technology is the process of mounting components by drilling holes in the circuit board and then inserting leads. This method creates a strong bond between the board and its components. It is known for its strong mechanical connection and higher power handling capacity. Thus, it is hot to use in aerospace, military hardware, and industrial machinery.

Mixed Technology (Combination of SMT and THT)

Hybrid technology includes SMT and THT. The mixed technology is ideal for complex, high-tech circuit boards to fulfill the required performance. They can solve complicated situations by choosing different assembly methods.

5 Popular PCBA Testing Techniques

PCBA testing is conducted to evaluate the product’s final performance. Here are the common techniques used for testing.

Functional Test(FCT Test)

FCT test is usually called functional testing, which tests the functionality of the entire PCBA and finds hardware and software problems.

In-circuit Test(ICT Test)

In-circuit test is to detect the continuity of the circuit, current and voltage values, fluctuation curves, amplitude, noise, etc.

Flying Probe Test

Flying probe test is done by using a “flying probe” to make contact with specific test points to detect the electrical performance of the PCBA.

Aging Test

Aging test is mainly to test the stability and durability of the product by testing the PCBA in long-term and periodic work and observing any failures.

Harsh Environment Test

Harsh environment testing mainly involves artificially creating environments with extreme temperature, humidity, water splashing, falling, and vibration to test the reliability of PCBA. Random sampling test results can be used to estimate the reliability of the entire batch of products.

What Are the Advantages of PCBA?

There are numerous advantages to employing PCBA in electronic devices. Here we introduce 5 common and prominent advantages.

Saves Time

Compared to the traditional method of connecting electronic components with wires, PCB assembly can be assembled faster with the assistance of automation.

Compact Design

PCBA assembles all components onto a circuit board, making it more compact and saving space.

Maximizes Durability

Copper etched onto the PCB board replaces the function of the wires, reducing the risk of exposed wire damage. PCBA uses advanced materials and components, which can improve product performance and make it more durable.

Simplifies Repair

If the PCBA is damaged, the corresponding faulty component can be replaced. This is far simpler than attempting to find the damaged part among a pile of wires.

Cost-effective

PCBA has achieved large-scale production, which can reduce costs. Its assembly process can be automated to reduce product defects, and rework times, and improve production efficiency.

How to Choose the Best PCB Assembly Company?

Here are the main things to consider when selecting the best PCB Assembly company.

Expertise

When you’re looking for a PCB Assembly Company, choose one whose primary business is manufacturing PCBA, not brokering or just providing services. Compared with these companies, a professional PCB assembly company has the expertise to provide high-quality products with guaranteed delivery times.

Quality

The quality is a major concern. The faulty PCBAs can affect the performance and operation of electronic equipment. When choosing a PCB assembly company, make sure they have quality control and testing procedures. Companies with quality management system certifications like ISO 9001 are more reliable.

Pricing

PCBA cost control is a significant step. This affects the final product cost. There is a need to manage budgets while ensuring that you get a high-quality product.

Lead Time

PCB assembly companies need to deliver on time so that your production schedule stays on track and the final product is completed successfully.

The Latest Trend in PCBA

PCBA has been evolving at a rapid pace to meet the needs of electronic devices. These are the latest trends at the moment.

Miniaturization and High-Density Integration

The ongoing drive toward high-density integration and miniaturization is a prevalent trend in PCBAs. They will continue to be smaller and compact to accommodate more portable and high-performance needs, such as wearables and handheld devices.

3D Printing

In PCBA manufacturing, 3D printing offers solutions to some key and difficult problems. This can print circuit boards with complex shapes and structures, as well as enable customization, which is difficult to achieve with conventional manufacturing techniques. At the same time, 3D printing can print some electronic components for electronic devices.

Smart Manufacturing

A vital emerging trend in the PCBA manufacturing process is smart manufacturing, which optimizes the production process by combining human and intelligent machine cooperation. It can raise productivity, cut expenses, and enhance product quality overall.

Continued Growth of IoT

The Internet of Things will continue to grow rapidly in the future, and PCBA technology will need to keep advancing. PCBAs play a critical role in the IoT. As the core component of electronic devices, it connects and controls various sensors, communication modules, etc. to realize intelligent and interconnected functions.

Conclusion

Now you should have a deeper understanding of PCBA. It is the basis of electronic devices and forms a complete circuit by assembling the required components on a circuit board. The emergence of PCBA has simplified the connection method of electronic components and provided a better order for the internal connections of electronic devices. Moreover, it accelerates the development of electronic technology and provides multiple directions and possibilities for the updating of electronic equipment.