Precision Through-Hole Assembly for Dependable Electronics - Choose UnityPCB

At UnityPCB, we specialize in THT(Through-hole technology) assembly, providing reliable PCBA for clients in different industries. We are able to assembly types of electronic components and complex PCB boards, making sure that each project can reach expected performance. Our flexible assembly capabilities allow us to handle prototypes and mass production runs with quick turnaround times.

We provide prototype assembly services before mass production to ensure that the assembled boards meet the design requirements.

UnityPCB can handle both small batch and large volume orders quickly, thanks to our cutting-edge equipment and proficient technicians.

To achieve specification compliance and guarantee the reliability and functionality of assembled PCBs, we source through-hole components from reliable manufacturers.

Our experts provide tailored assembly solutions based on specific project requirements and unique design needs, ensuring you get exactly what you want.

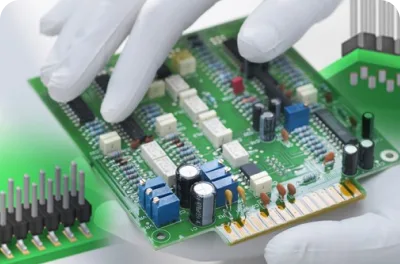

Source required components and check their quality, then clean the PCB to ensure optimal surface conditions for assembly.

Through-hole components are precisely placed into the PCB holes using either automated insertion machines or skilled manual technicians for complex parts.

Boards undergo wave soldering or selective soldering processes. Wave soldering creates uniform connections, while selective soldering targets specific areas for heat-sensitive components.

After soldering, the assembled boards go through optical tests as well as AOI and ICT electrical checks to verify proper assembly and functionality.

Our team has been working for more than ten years in PCB industry to provide highest quality through hole assembly services.

Customized designs tailored to your specifications, with flexible assembly capabilities accommodating both small sample production and mass production orders.

At UintyPCB, we have streamlined processes and efficient production lines to ensure quick turnaround times while maintaining high standards.

We carry out a series of testing methods including AOI and ICT to guarantee the performance and durability of your assemblies.

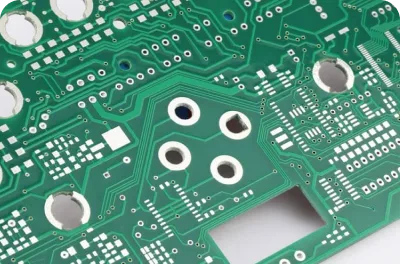

By definition, Through-Hole Technology (THT) Assembly refers to an electronic assembly process where components are inserted through holes in printed circuit boards.

There are some advantages of THT assembly; it offers good adhesion and enhanced mechanical strength making it suitable for parts that are subjected to mechanical forces.

THT involves the placing of parts putting into holes that have been drilled on the PCB while SMT entails placement of parts on the surface of the PCB. THT provides stronger mechanical bonds, whereas SMT allows for higher component density and automation.

THT assembly often employed components like resistor, capacitor, inductor, and connector leads through the PCB.

Yes, UnityPCB has the capability to undertake both THT and SMT mixed and hybrid technology boards.

Absolutely. UnityPCB has vast capabilities in sourcing of required components. To maintain the quality of your assembled PCBs, we source through-hole parts from reputable vendors and integrate these into your circuitry.

Contact Us