Delivering Unmatched Precision and Reliability in SMT PCB Assembly for All Your Electronic Needs

Surface Mount Technology (SMT) assembly is more widely used than thru-hole assembly and other component mounting processes due to its accuracy and numerous benefits. This method allows components to be directly mounted onto the board. At UnityPCB, we apply expertise and satellite technology in providing first class SMT PCB assembly. Our expert team ensures precision, reliability, and cost-effectiveness for all your electronics manufacturing needs.

We provide PCB assembly prototyping service with rapid production and flexible design modifications, ensuring optimal performance before full-scale production.

Our scalable manufacturing capability can handle surface mount PCB assembly from small batches to high-volume runs to meet different customer needs.

UnityPCB provides comprehensive SMT assembly service, from PCB design, component sourcing, PCB board fabrication, to assembly, testing, and shipping.

We offer customized solutions that are tailored in meeting specific needs, including sourcing non-standard components, and handling complex designs.

A precise amount of solder paste is applied through stencil printing for proper connection of components and board.

We perform solder paste inspection(SPI) to ensure accurate paste deposition, preventing defects and ensuring high-quality SMT assembly.

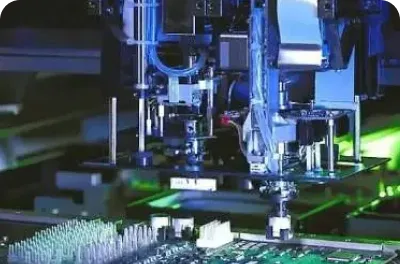

Advanced pick-and-place machines accurately position components onto the PCB, following the design specifications with high speed and precision.

The PCB passes through a reflow oven, where controlled heat melts the solder paste, creating permanent connections between components and the board.

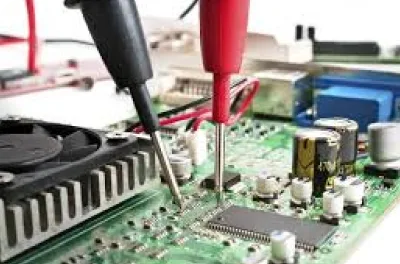

Thorough testing and inspection for assembled PCBs covers AOI, X-ray inspection, and functional testing that guarantees both quality and performance.

Our team’s years of expertise help to guarantee stable and high-quality results in various PCB projects and industries.

Our production capabilities are flexible, we adapt them based on clients needs, from prototypes to large scale productions.

we employ stringent quality control measures coupled with state-of-the-art inspection techniques in order to deliver high-quality PCBA always.

We can complete PCB assembly quickly while still maintaining the best quality possible through our efficient working methods.

SMT (Surface Mount Technology) PCB assembly is the process of mounting electronic components on surface of PCB directly. This technique also makes it possible to have more components per unit area and designs that are comparatively smaller, than those in through-hole assembly.

The benefits that can be gained from SMT Assembly include increased component density on the PCB, improved electrical performance, reduced cost due to automation, improved reliability, and increased durability.

Fine pitch attachment refers to connect and place elements where the leads have a small pitch. This requires precise equipment and expertise to ensure accurate placement and soldering without causing shorts or defects.

Yes, UnityPCB has the capacity of prototyping minimum quantity and mass production to meet customer needs and demands appropriate for any production scale.

Overall, lead times fluctuate with the complexity of the projects being implemented and the order quantity. At UnityPCB, a prototype runs for about 5 to 10 days, while production runs may take 2-4 weeks.

Yes, we have experience with flexible and rigid-flex PCB assembly.

Contact Us