Are you attracted by a PCB in different colors, such as red, purple, white, black, etc.? Some circuit boards require a more aesthetic appearance, so other colors are used. Thanks to technological advances, there are many options for PCB colors, not only green. Different colors can showcase the unique styles of various circuit boards, creating an attractive first impression and helping to enhance the overall product experience. Next, we will introduce different types of PCB colors in detail, and give you more information on how to choose PCB colors.

What Is a PCB Color?

PCB colors refer to the color visible on the board. That is the color of the solder mask and silkscreen layer. The solder mask layer is used to cover the copper traces on the circuit board, protecting it from damage and short circuits. Green is typically the predominant color, but it is not the only one. Red, blue, and purple are also common PCB colors. The silkscreen layer’s function is to label words and symbols. White and black are the most common silkscreen layer colors, but others can be used. When we talk about PCB colors, we generally refer to the colors of the solder mask.

Why Do PCB Colors Matter on Circuit Boards?

There are more color options for PCBs than ever before. A few of the elements that highlight the significance of circuit board color are described below.

Protection Circuit: Guard against oxidation and corrosion of traces on boards. Protect circuit boards from damage by environmental factors, reduce the risk of short circuits, and improve reliability and service life.

Visual Appeal: Color is an important part of increasing the visual appeal of PCB. According to different markets, products, and user preferences, adjusting the PCB colors can improve the competitiveness of products.

Easy to Check: The colors of the solder mask and silkscreen layer should contrast to allow for easy inspection and ensure the readability of information on the board.

Differentiation: In complex electronic devices, special PCB colors can help quickly identify circuit boards and make repairs.

Environmental Friendly: Some industries require that PCB colors adhere to environmental standards and applicable safety regulations.

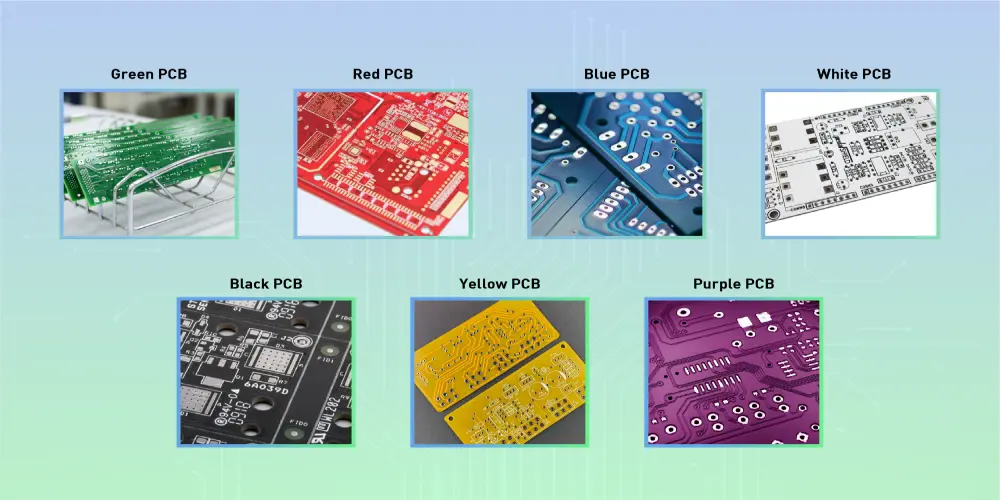

Understanding 7 Popular Types of PCB Colors

With technology advanced, there are many kinds of colors used in circuit boards, not just the typical green. Here we will go over 7 popular kinds of PCB colors in detail.

Green PCB

In many devices, the most popular color of the circuit board is the green one. It is the standard and common PCB color. Since the green color can have better visibility and contrast, it is easy to find the defects and identification on the circuit board. Usually, green solder masks and white silkscreen layers are common combinations.

Red PCB

The red PCB is a board with a bold, bright color that is attractive and aesthetically pleasing. Red board color also offers additional advantages, including excellent visibility, and sharp contrast, making it easy to spot damage issues on the circuit board. Thus, red is an alternative choice for the common green solder mask on circuit boards. However, compared with the green board, its contrast is lower. You can find red PCB in high-end products, like audio equipment, gaming motherboards, and high-performance graphics cards.

Blue PCB

Blue is also a popular color used in circuit boards. It is a good color to contrast with the silkscreen and trace. It should not only have a good aesthetic effect but also have a strong contrast with the silkscreen layer and the trace to ensure that the trace is visible and the information is readable. Therefore, Blue PCB is often used in more complex circuits, such as robot circuits.

White PCB

The white PCB looks very clean and high-end. It is often paired with a black silkscreen layer for better contrast. White circuit boards are more difficult to clean and inspect. However, in LED systems, white PCB produces brighter light than traditional colors.

Black PCB

Black PCB has a high contrast with white silkscreen. It is easy to identify the symbol labeling on the board. Instead, black is a deep color, it’s hard to find the traces. This is also a challenge for the inspection circuit. And black PCB will absorb heat during the reflow process.

Yellow PCB

Yellow is a brighter color that can highlight the appearance of the PCB. Instead, it provides relatively poor contrast with traces. Therefore, It is hard to use in electronic applications.

Purple PCB

Purple shares some characteristics with blue and red, and it can provide a contrast with the silkscreen. The traces are harder to see because purple is a darker color. Purple is not used very often, usually by special request or to match the product.

Why Are Most Circuit Boards Usually Green?

There is a vast use of PCBs in people’s daily lives, and a majority of them are green. These explanations will help to clarify why.

Material: The most direct and potential reason is that the material “Glass epoxy” was commonly used to make solder masks in the past. It is green, so the PCB is also green.

Sharp Contrast: The green PCB’s solder mask and silk screen layers form a sharp contrast. The symbols and words on the silkscreen layer are usually in white contrast. It’s easy to see the traces and inspect boards.

Easy to Detect: The circuit board can be inspected by an automatic machine, like the AOI system. Human inspection is also important in the manufacturing process. Green can reduce eye fatigue and make it easier to see each part.

Manufacturing Cost: One of the crucial advantages is its stable and relatively mature manufacturing method. It allows manufacturing in large quantities that also affect the cost of the manufacturing as well as time-to-delivery.

Environmental Friendly: The actual production is well-developed and constantly optimized to minimize the emission of hazardous substances and the use of waste products.

What to Keep in Mind When Choosing PCB Colors

These are some tips that should run through your head when selecting PCB colors.

Cost Consideration: In the case of the PCBs, green is the color that is used more often than any other color. This means that manufacturers can buy raw materials in large quantities to produce a large number of products. The cost of production will be low. Other colors may need to be manufactured differently and hence they would be relatively expensive.

Aesthetics: While creating an electronic device today, it is not only the functionality that is central but also the aesthetic of fashion. In comparison to green color, black looks more like a faction and suit for a high-end modern product.

Brand Recognition: Deciding to adopt your own brand’s color as the color of PCB is a good strategy to employ in market competition. When people see this PCB color, they will remember your brand.

Component Visibility: When choosing PCB colors, there are many factors that need to be considered such as component assembly and testing process, etc. PCB colors have good contrast which can enhance the speed of the assembly and inspecting process.

Thermal Management: Thermal management is important for the majority of electronic devices, especially for high-power electronic devices. Dark-colored circuit boards absorb more heat, such as black and purple PCBs.

Final Words

Although PCBs are now available in a variety of colors, green is still the most used color. Choosing the color of a PCB is a process of balancing function and aesthetics. To pick the best PCB color, you must take into account a number of elements. In the future, PCBs will use more and more colors to create wonderful aesthetic appeals while also ensuring their superior functionality.