When talking about circuit board manufacturing, you will often see the two terms (PWB vs. PCB) used interchangeably. They look similar, but they are very different in terms of design, manufacturing, and application. To help you clear up any confusion PWB vs. PCB, we will go into great detail about their differences in this article.

What Are Printed Wiring Boards (PWBs)?

When early circuit boards were invented in 1903, they were called PWBs. PWBs have conductive traces etched or printed on a non-conductive surface. The circuit design was relatively simple, relying primarily on basic wiring to provide pathways for electrical connections. PWBs had no embedded components and were mainly used for basic electrical connections.

What Are Printed Circuit Boards (PCBs)?

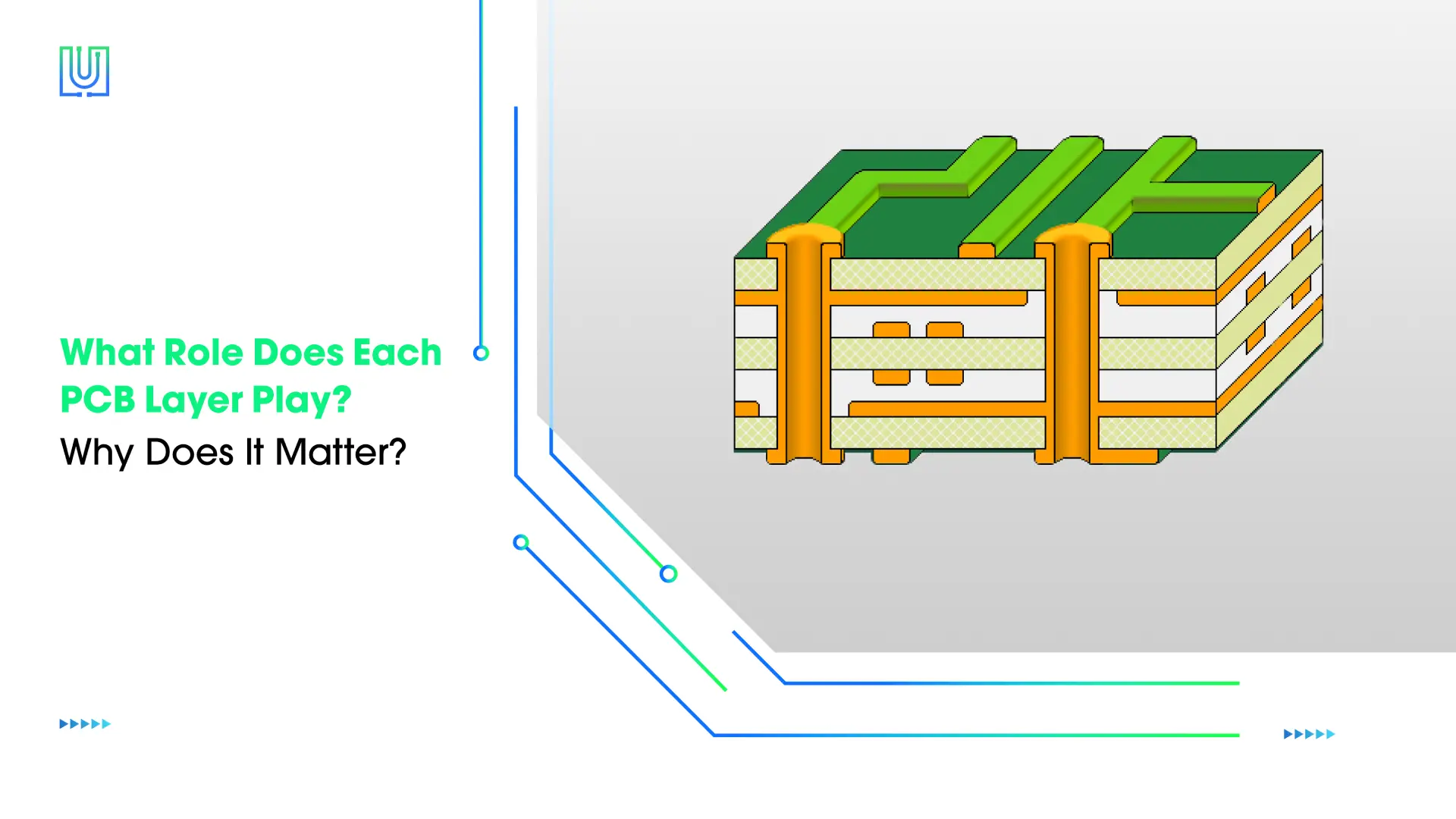

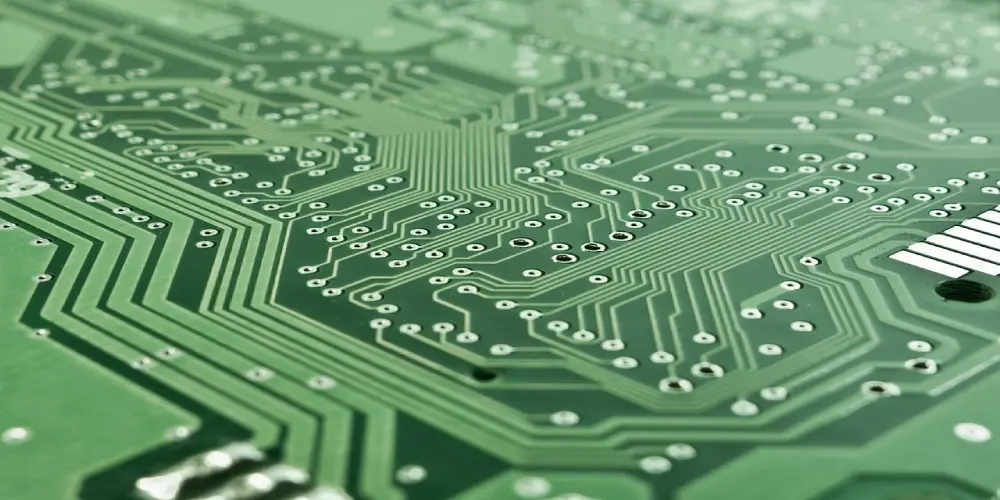

PCB is a more sophisticated circuit board that evolved from PWB. Its tracing is more intricate and dense. Multiple technologies can be used to install different electronic components on the board such as integrated circuits, resistors, and capacitors. This type of circuit board allows electrical signals to be transmitted from one side of the circuit board to the other side and also supports signal connection between different layers. Depending on the circuit’s intricacy and the quantity of components needed, they can be single-layer, double-layer, or multilayer.

PWB vs. PCB: Key Differences Explained

After a basic understanding of PWB vs. PCB, we will analyze the main differences between them.

Different Uses of Terminology

The difference in PWB vs. PCB stems from their technological development history. PWB vs. PCB both refer to a board that can connect and support electronic components. PWB normally describes a simple single-sided board having circuits connected through point-to-point wires. PCB is now a more generic term for single, double, and multi-layer circuit boards and allows for more complex component integration. It is frequently used PWB vs. PCB interchangeably in the industry. If you don’t want confusion while talking about them, it’s best to specify which one you are referring to.

Complexity of Design

A key difference between PWB vs. PCB is the complexity of the design. PCB is usually more complex than PWB. PWB is generally a single-sided board with conductive traces on one side of the substrate. Connections between components on a PWB rely on simple wires. There are no complex paths or multi-layer connections involved in the circuit design. This kind of circuit board works well with basic devices and applications.

PCB has a higher design complexity and supports the multi-layer structure and complex circuit layout. It needs software for detailed circuit design and stack-up design. It must take into account elements like impedance matching, signal integrity, and thermal management. Multi-layer PCB design helps to achieve higher component density, which helps to achieve complex circuit design.

Different Manufacturing Technology

There are obvious differences in the manufacturing technology of PWB vs. PCB, which is mainly reflected in their process complexity and performance requirements. PWB adopts a relatively basic manufacturing process. It mainly uses photolithography or screen printing for pattern generation, and chemical etching to form wires. This process is suitable for manufacturing single-sided boards with a simple design and low component density.

The manufacture of PCBs, especially multilayer PCBs, requires more complex processes. Multilayer PCBs need to use vacuum presses and optical alignment systems for precise inter-layer alignment and lamination. Advanced technologies such as sequential build-up (SBU) or semi-additive process (SAP) are used to achieve high-density interconnection. These process differences directly determine the performance and scope of the application of PWB and PCB in practical applications.

Performance Comparisons

As for performance, PCB shows all-around advantages over PWB. With its excellent and sophisticated design, PCB can support high-speed, high-frequency signal transmission and ensure better signal integrity. However, PWB is more susceptible to signal interference and has obvious limitations when processing high-frequency signals. Regarding reliability, PCB has stronger thermal management and anti-interference capabilities, and it has a longer service life.

Exploring the Applications of PWB and PCB

PWB is suitable for simple circuits that require basic electronic functions and do not involve high-density components. PCB is suitable for applications with higher requirements for component density, complex circuit design, and high-performance applications. Here we list the different applications of PWB vs. PCB in the same field.

Consumer Electronics

PWB: Commonly used in various simple consumer electronic devices, such as computers, simple electronic toys, and remote controls, where simple wiring connections are sufficient. PWB is a low-cost, cost-effective choice.

PCB: Widely used in electronic consumer products such as computers and mobile phones. It provides the basis for mounting and connecting high-density components, such as processors, communication modules, and memory chips. The complex design and multi-layer structure of PCB support high-speed data transmission.

Industrial Equipment

PWB: Used in industrial equipment that requires simple basic connections, such as basic relay boards, simple control panels, temperature sensors, etc.

PCB: Commonly used in industrial automation control equipment, test and measurement equipment. They require extremely high reliability to withstand harsh conditions in industrial environments such as vibration, extreme temperatures, and exposed chemicals.

Automotive Electronics

PWB: Used for simpler automotive electronics such as lighting controls, sensor interfaces, and simple instrument panel displays.

PCB: Can be used for control systems and safety functions like airbags and ABS. These applications require high component density and high reliability to achieve more complex functions.

How to Choose Between PWB and PCB for Your Needs

When selecting a PWB vs. PCB for your project, there are numerous considerations to take into account. Below we list 4 key factors to consider and explain PWB vs. PCB in detail.

Cost and Budget Considerations

Cost is usually the main factor, and the choice is based on your project budget, but also consider production volume. PWBs generally use simpler manufacturing processes and materials, which can make them more cost-effective in simple applications. In small-volume production, the simple manufacturing process of PWBs also has cost advantages. However, as production increases, PCBs can be mass-produced, which can reduce costs. Due to more complex manufacturing techniques, PCBs (especially multi-layer or high-density designs) may involve higher production costs.

Design Complexity

Design complexity is another key aspect. PWBs are suitable for circuits with simple, low-density components. They generally have a single-layer structure and are more easier and faster to produce. PCBs allow for more complex designs, including the ability to accommodate higher-density components and more complex routing. If your project requires advanced functionality, integrated circuits, or high-performance features, you may need a PCB.

Performance and Reliability

Performance and reliability are considerations that will greatly influence your choice. PWBs may not be able to fulfill the performance needs of contemporary electronic devices, but they can be utilized for simple, basic applications. PCBs have obvious advantages in signal integrity, thermal management, mechanical stability, and environmental resistance due to their multilayer structure and the use of special materials. This increases PCB’s ability to adjust to the high-performance needs of contemporary electrical devices.

Manufacturing Restriction

The decision-making process is also constrained by manufacturing constraints. Some manufacturers might focus on producing high-volume PCBs with advanced capability or just simple PWBs. Advanced PCB manufacture requires more complex methods and tools with greater costs and longer lead times. For projects with lower volumes and tighter budgets, PWBs make a better choice. To achieve your perfect choice, it is important to comprehend the benefits and drawbacks of your manufacturer.

Understanding Other Terms Related to PWB and PCB

If you work in the electronics industry, you need to understand related terminology with PWB vs. PCB. We introduce a few terms below related to PWB vs. PCB.

PCBA: PCBA refers to a circuit board with electronic components assembled. It is directly used and capable of accomplishing particular tasks. This also refers to the process of mounting electronic components on circuit boards. The full name of this term is Printed Circuit Board Assembly, we can also call it PCB Assembly. PCBA has become a more accurate and unified term and has gained wide acceptance as the preferred expression.

PCA: PCA is the same as PCBA, and its full name is printed circuit assembly. However, this word is seldom ever used.

PWA: It stands for printed wire assembly. Early circuit design in which links between components are made using wires. However, with the development of technology, PWA was naturally replaced by PCBA. PCBA supports multi-level connections and higher functional requirements, becoming the mainstream choice for modern electronic devices.

CCA: It is an abbreviation for Circuit Card Assembly, which has the same meaning as PCBA, referring to an assembled circuit board. However, CCA is a less widely used term.

Final Thoughts

PWB vs. PCB represent different stages in the evolution of electronic circuit board technology. Early PWBs only provided a platform for connecting components with simple wires. As technology advanced, the PCBs we use today have evolved from the original PWBs to more complex and versatile circuit boards. Its emergence has enabled electronic manufacturing to move from simple circuits to modern high-performance electronic devices. Now, the term PCB is more commonly used to refer to today’s printed circuit boards.