In the electronics industry, most PCBs are usually green, which is the traditional color. As market demand changes, more and more PCB manufacturers are beginning to choose PCBs with bright colors, such as purple PCB, yellow PCB, red PCB, blue PCB, etc. Purple is a charming color that can beautify PCBs and make your project stand out. Next, let’s look deeper at purple circuit boards.

What Is a Purple PCB?

As the name implies, a purple PCB is one that has a purple solder mask rather than the more conventional and typical green one. To shield the copper traces from oxidation and contaminants in the workplace, the solder mask is placed over the copper layer. As technology has advanced and market need has changed, it has gradually become a trend. The attractive purple color also enhances the aesthetics of the entire product. Choosing a purple circuit board as your own unique and iconic PCB can help consumers distinguish your products from other brands.

How to Produce Purple Solder Masks

We typically use two methods to produce purple solder masks on the printed circuit boards. Let’s explore them in detail.

Adding Purple Pigments to the Mask

This method adds the purple pigment directly to the solder mask material before applying the mixture to the board. The circuit board is cured using UV light and heat to achieve the desired purple color for the solder mask.

Advantages:

- A uniform purple solder mask can be provided over the entire board, and the PCB will look more beautiful.

- Using LED curing can provide greater flexibility in integrating pigments.

Layered Base with Purple Legend Ink

The basic light-colored mask layer is applied to the PCB surface, which provides a background canvas. Then, you can selectively apply the purple legend ink on the mask to protect the areas that need to be prevented from soldering. Purple ink printing requires accurate registration to avoid leaving any unnecessary exposed areas. The purple ink will appear bright purple on the light mask layer.

Advantages:

- The layering approach can reduce the overall mask thickness.

- Different areas of the board can use different colors, providing more design flexibility.

Pros and Cons of Purple Circuit Boards

Here, we go over the benefits and limitations of purple PCBs, so you can fully comprehend them.

Pros:

- Visual Differentiation and Aesthetic Appeal

They are a differentiated choice among the many green PCBs, with a strong appeal. The unique purple color can make your project a popular choice among the masses. Especially in consumer electronics, the internal design is also a point of distinction.

- Marketing and Branding

Purple PCB can help you enhance your brand visual identity and create a unique brand image, which is difficult to do with green PCB. You can combine your brand values and concepts with it to form a unique selling point for your product. Purple gives people a high-end, fashionable feeling that can help enhance your brand image and market recognition.

- Easy to Identify

When manufacturers produce many types of PCBs at the same time, purple printed circuit boards can easily help identify specific models and product lines. Their prominent color can distinguish them from other products.

Cons:

- Higher Price

The purple solder mask materials are more expensive compared to the usual green solder mask material. Besides, there is relatively less demand for purple circuit boards, which require a specialized production process. Its cost is generally higher than that of standardized green PCBs. Projects that have very strict budgeting will find that the additional cost of the purple PCB is one that simply can’t be afforded.

- Prolonged Lead Times

The materials for the purple solder mask require specialized procurement. It is not as commonly used as green solder masks, which manufacturers purchase materials in bulk. Applying purple solder masks is not a standard production process. Extra steps may be required during the process of applying and curing purple solder masks to ensure uniformity and consistency. This increases the complexity and time costs of the manufacturing process.

Applications of Purple PCBs

Purple PCBs are increasing in popularity across various industries, primarily due to their aesthetic properties. They can also play a specialized functional role in certain aspects. Here are the key applications where they are commonly used:

Consumer Electronics

You can see them in many consumer electronics. The purple color can give these products a more stylish, high-end look that visually appeals to consumers. Below are some typical samples.

- Smartphones, Tablets

- Gaming consoles, Gaming accessories

- Audio-video equipment

Electronics and Gadgets

They are chosen by startups or innovative companies that want to make their electronic products look different. This can help attract customers by the bright color and create an emotional connection. Especially for those devices with transparent shells, the purple core shows more. Devices like power banks just pop into your head.

Fashion-Forward Wearables

Wearable devices, such as smartwatches and VR headsets, are increasingly using purple PCBs to add to their aesthetic advantage and uniqueness. Purple gives the impression that the product is an extension of the wearer’s individuality.

DIY and Creative Projects

Purple is a symbol of preference, personality, and self-expression. In DIY and maker space projects, the alluring color can inspire enthusiasts’ interest and passion and drive the development of the project.

Toys and Educational Kits

Purple PCBs may be used in some children’s educational kits or electronic toys. This is more visually appealing and fun, especially for younger audiences.

Prototyping or Experimental Circuits

In experiments or prototyping, they can be used to differentiate from standard green versions, allowing quick identification of prototypes, iterations, and variants.

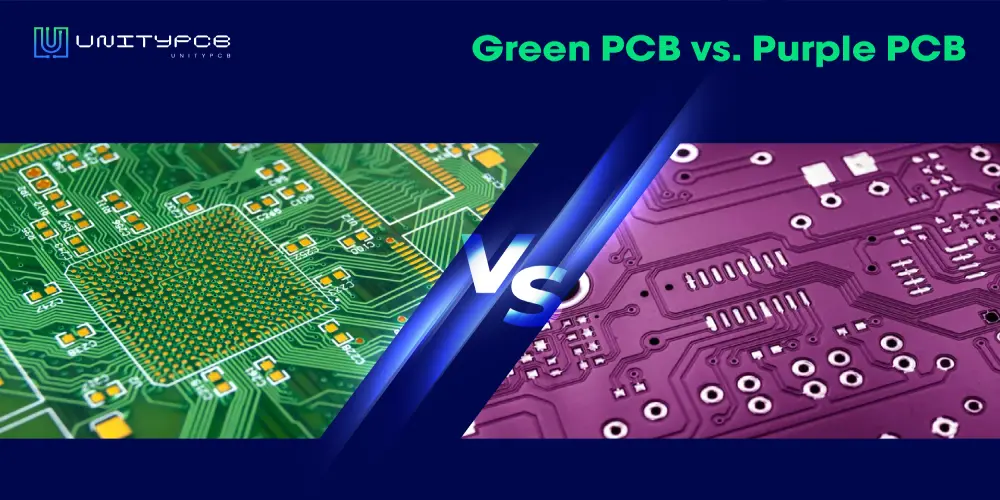

Purple PCB vs. Green PCB

This is a table that provides a comparison between purple PCB and green PCB from the following aspects.

| Aspect | Purple PCB | Green PCB |

| Solder Mask Color | Purple | Green |

| Manufacturing Cost | Generally slightly higher | More common, lower cost |

| Market Prevalence | Less commonly used | Most common, widely used |

| Component Visibility | Lower, harder to spot | High, easy to inspect |

| Application Range | High-end, custom products | Standard, regular applications |

| Aesthetic Appeal | More unique | More traditional, classic |

| Manufacturing Process | Less common, slightly more complex | Mature production, stable process |

| Brand Perception | Often seen as premium or unique | More mainstream and reliable |

| Manufacturing Lead Time | Slightly longer due to lower production volume | Faster due to high demand and established processes |

| Recyclability | Additional dyes and colors make recycling more challenging | More common, more environmentally friendly design |

If you want to know more about PCB colors, it is recommended that you read this article. PCB Colors Explained: Selecting the Perfect Color for Your Circuit Board

Frequently Asked Questions

I think you understand purple PCB quite well after reading the content above. The following are some frequently asked questions about them, hoping to answer some doubts you may still have.

Q1: Why Do More PCBs Come in Green Than Purple?

Green PCBs became the standard for very many years due to their ease of manufacturing and availability of materials. With advancements in technology, purple printed circuit boards are now more available at a more reasonable cost.

Q2: Are Purple PCBs Suitable for High-Frequency Applications?

Of course, they can be used in high-frequency applications, and functionality is unaffected by the color of the solder mask.

Q3: Do Purple Boards Work with Standard Assembly Techniques?

Of course, it is compatible. It can be compatible with standard PCB through-hole component soldering or surface mount technology. PCB assembly process compatibility depends on the PCB materials and layout design. Certain assembly steps may require optical alignment, and green provides better visibility. This does not mean that Purple PCB is incompatible, it just requires extra attention to ensure alignment and assembly.

Final Words

Purple PCBs are a technological innovation that combines functionality and aesthetics. While they may cost a bit more and take longer to deliver than green PCBs, their unique look can provide significant value for brand differentiation and product identification. Whether it’s consumer electronics, wearables, or creative projects, these circuit boards offer an innovative way to combine performance with visual appeal.

Purple PCB is a good option if you want your project to stand out. Welcome to consult UnityPCB about all services related to PCB, whether it’s purple or other color circuit boards, we will be committed to meeting your needs.