Quality Control

PCB X-ray inspection is a popular PCB testing technique that uses X-rays to check the quality of the PCB and detect hidden defective areas without harming the board. At UnityPCB, we use the most advanced PCB X-ray machines that enable us to identify hidden assembly defects and maintain the quality of products.

PCB X-ray inspection is also referred to as Automated X-Ray Inspection or AXI. This system employs an X-ray as a scanning source, which can capture internal geometries and structural compositions without causing damage to the part under examination. It is most effective in identifying large voids and cracks, meanwhile, all the SMDs and their solder joints can be inspected. It is also equipped with software that produces actual- time 2D images of components, and with the help of those images, we can easily visualize and analyze the defects in the board. More importantly, we can also figure out the cause of each issue by using this key PCB testing method.

PCB X-ray inspection is based on the measurement of X-ray photons that go through a certain material. Various materials contain various proportions of the elements and thus, their atomic weights vary as well as X-ray photons react in a specific manner when encountering definite elements. In this case, heavier elements usually look darker in comparison with lighter elements that seem more transparent, and this ultimately gives way to dynamic X-ray images. Because PCBs are generally constructed of heavier elements, a more precise pictorial description can be easily realized through x-ray visualization. PCB X-ray inspection equipment generally includes three main components:

• X-ray Tube: The X-ray tube plays a significant role of producing the X-ray photons, which is also known as a Roentgen tube. It works to accelerate electrons to high velocities and then cause them to crash into a target.

• Sample Handling Platform: To request X-ray inspection from all angles, the platform of the X-ray machine is employed to shift the PCB sample in all directions.

• Detector: The detector receives the X-ray photons on the other side of the sample PCB and forms an image out of it. This may be in an ordinary 2D format or a detailed 3D picture, depending on the software that is used.

• 2D system: A 2D x-ray system shows the front and back sides of the PCB at the same time to form the picture of the board. This is in a similar vein to what was previously thought of where an x-ray was used for looking at bone fractures. 2D Systems can be used either in an online mode or offline mode.

• 3D system: A 3D x-ray system is capable of constructing a three-dimensional picture of PCB by collecting a series of two-dimensional images of the cross-sectional plane. This is in the same way that CT scans in general work in the medical field. 3D X-rays also operate using the laminography technique where consecutive cross-sections are added up in a particular portion or region. It is notable that the CT method can only be performed offline because of the complex algorithms involved, while the laminography method may be performed both online and offline.

• Online operation:There are some X-ray devices that are used on the internet for data collection and comparison. This makes it possible to handle increased complexity and large volumes of PCBs. Still, the con of having online capability is that it slows down the operation of the X-ray machine thereby demanding more cost for less capacity.

• Offline operation: All the x-ray devices can be operated in offline mode for the purpose of panel inspection and sampling inspection. Offline tools are normally fast to compute but they are not so suitable for large quantities of products.

• Blind and Buried Via Issues: X-ray machines have the ability to scan areas not easily accessed, which enables the inspectors to evaluate the soundness of holes and connections in the PCBs such as blind and buried vias.

• Ball Grid Arrays (BGAs) Defects: X-rays can pass through well-sealed BGA components and therefore allow inspectors to see defects in PCBs and mounted components that would otherwise be quite difficult to see because of their compact positioning.

• Decoupling Capacitor Placement Errors: By implementing the AXI, we can check if decoupling capacitors are correctly placed, which is crucial for power stability. The wrong place of them can reduce the performance and even cause explosions.

• Solder Voids: By using PCB X-ray inspection, we are able to pinpoint solder voids that can lead to poor connections or product quality. It is difficult to find such a problem by visual inspection due to the density of the BGAs.

• Filled Pin Holes: AXI can also detect the filled pin holes in plated through-holes. This issue is caused by gas escape during the soldering process, which affects connection reliability.

Advantages

Internal Inspection Capability: With the use of AXI, we can check the internal structures, hidden solder joints, as well as components that may be invisible from the surface of a PCB.

High Accuracy: The technique provides a clear image thus making it easy to identify kinds of flaws even the minute ones that are hard to identify by other inspection methods.

Suitable for Complex Assemblies: Automated X-ray Inspection is suitable for checking multi-layer boards and densely packed components such as Ball Grid Arrays (BGAs) and Quad Flat Non-lead (QFNs),

Quantitative Analysis: Advanced AXI systems can deliver qualitative data associated with solder joint quality, components placement and other important parameters.

Disadvantages

High Initial Cost: AXI is usually costlier than other common inspection technologies due to high initial investments in equipment.

Radiation Safety Concerns: Safety issues must be considered when using X-rays, and special modifications to the facility and training for operators may be needed.

Limited Surface Defect Detection: Although AXI can provide very good results in the internal inspection of printed circuit boards, it may be less reliable than Automated Optical Inspection (AOI) in the identification of external defects on PCBs.

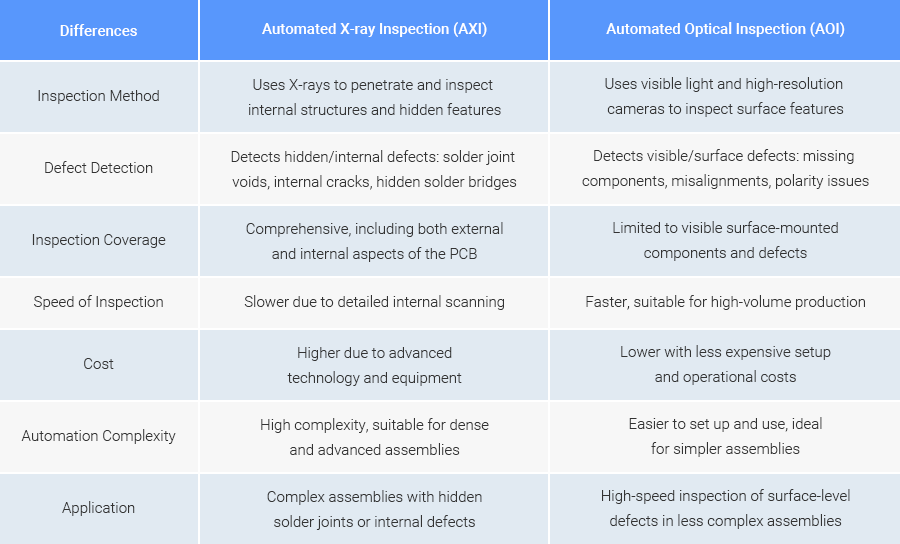

Although AXI and AOI belong to the category of structural testing and inspection methods that use image capture for the examination, each of them has specific properties and functions. To better understand their differences, we list a table below:

PCB X-ray inspection is important because it can reveal hidden problems such as BGA packages and voids in solder joints. This helps to minimize the production of unreliable and substandard PCBs.

Yes, if the proper safety protocols are followed. Today, X-ray inspection systems are well shielded and there are safety interlocks to reduce exposure levels.

X-ray inspection can identify a number of defects, including but not limited to solder joint voids, BGA connections, misaligned components, insufficient solder, short circuits, and filled via holes.

X-ray inspection is most useful in cases where the circuit assemblies are intricate, and when the connections are hidden like BGAs.

No, AXI complements other techniques such as AOI and In-Circuit Testing (ICT) since AXI detects internal defects that other techniques cannot. It is most effective if used as one of the many tools in the quality control process.

Elevate Your PCB Quality with UnityPCB's Rigorous Testing Solutions

Contact Us