When working on electronic projects, one of the main decisions one has to make is between PCB vs Breadboard for circuit design and testing. Both of them are useful tools, but suitable for different stages- breadboards are normally used in prototyping to test the design, while printed circuit boards (PCBs) are commonly used for finalized design and production. In this blog, we will compare PCB board and breadboard by explaining their definition, listing their key differences, advantages and disadvantages, and provide guidance on when to use each. Let’s dive right in.

What Is PCB?

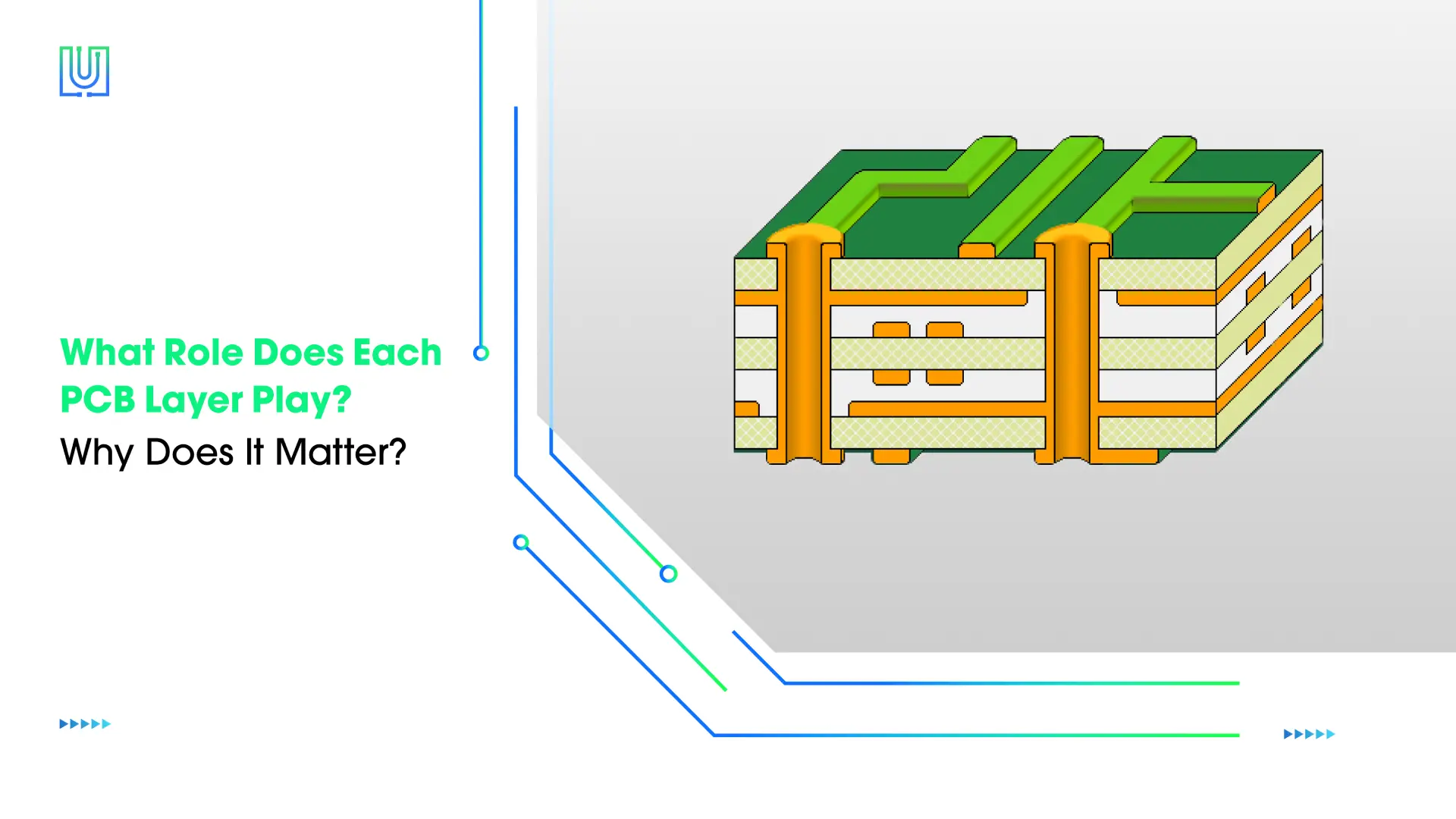

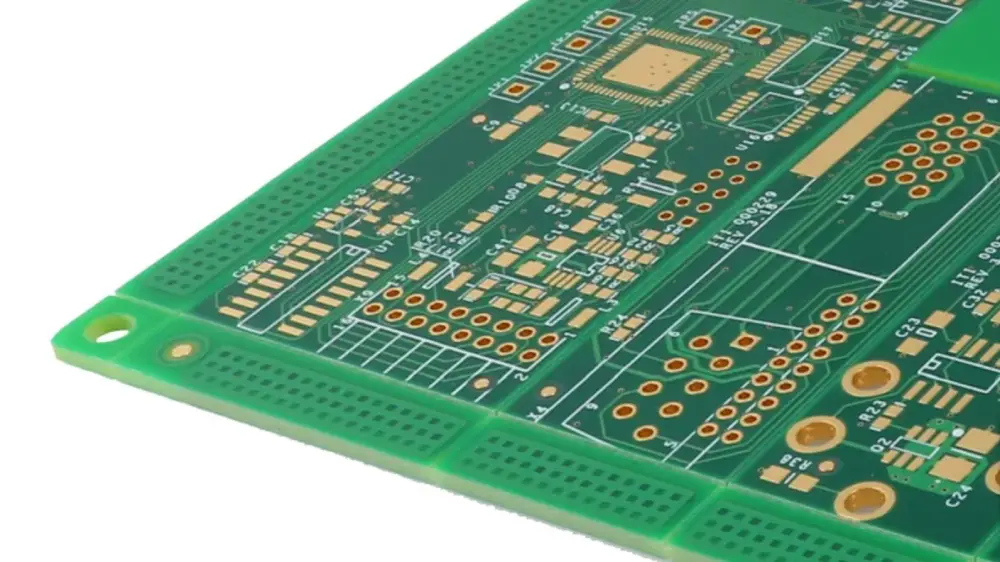

PCB, with the full name of printed circuit board, is a flat, non-conductive board that is typically made from materials like fiberglass or composite epoxy. On the one hand, it provides a mechanical platform for electronic components to be assembled. On the other hand, it allows mounted components to be electrically connected through the conductive pathways that are etched and printed onto its surface. We can find PCBs in almost all modern electronic devices such as smartphones, tablets, smartwatches, and so on.

How Do Circuit Boards Work?

PCBs work by establishing a controlled pathway for electricity to flow between components, such as capacitors, ICs(integrated circuits), and resistors. Each trace on the PCB is strategically placed to form a specific circuit design, so power and signals get to the right components, without interference. The non conductive board isolates each trace preventing short circuits. For complex designs, multiple layers can also be added to PCBs to connect to multiple circuit pathways within each layer, through small drilled holes also known as vias, to create intricate and multi functional circuits.

What Is a Breadboard?

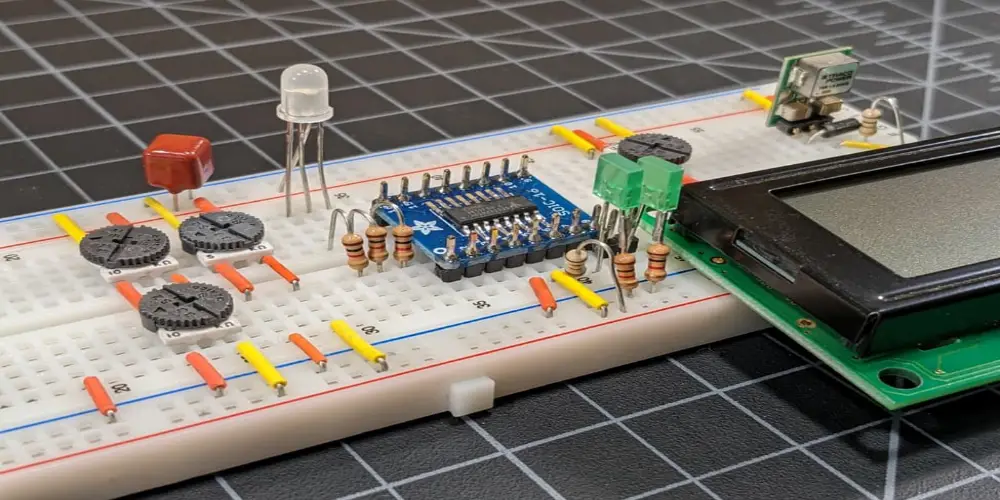

A breadboard refers to a board that is typically used to make prototypes and to build circuit to verify designs. Unlike PCB, it allows people to place components and make connections without the need of soldering. There are many holes in the breadboard, which can hold components and wires firmly, so as to create electrical connections within the board. It is a convenient tool as it allows designers to remove and replace components easily. Therefore, if you are working on a project that is still in the design testing phase, breadboard would be a good choice.

How Does It Work?

The breadboard’s functionality lies in its interconnected metal clips or terminals arranged systematically in rows and columns on the breadboard. Typically, the A, B, C etc. represent each column, and the numbers are each row for easy reference. Electronic components are inserted into particular terminal holes and it’s quite easy to put together a circuit. The metal clips automatically create the electrical connections, but jumper wires can also be added to connect different points. The flexibility of the circuit configuration and ease in modifying the experiment during the process have been achieved through this design.

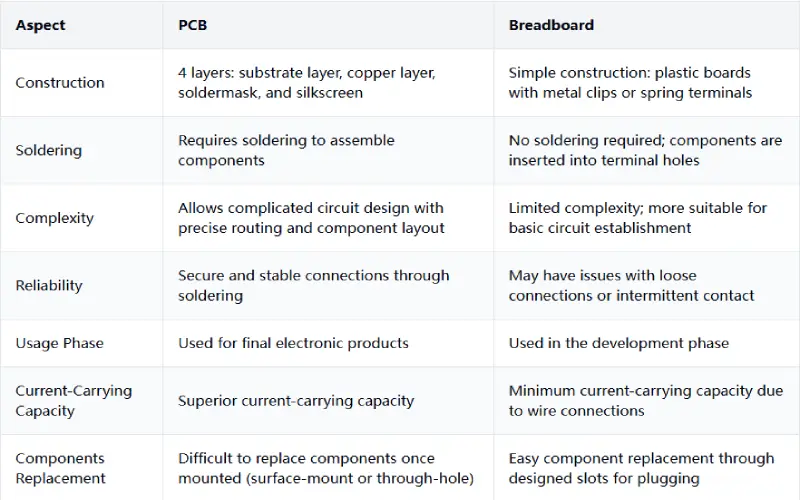

7 Key Differences between PCB and Breadboard

PCB and breadboard are different in below key aspects:

- Construction: The basic construction of PCB include 4 layers: substrate layer, copper layer, soldermask, and silkscreen; while the construction of breadboards is much simpler: plastic boards with metal clips or spring terminals.

- Soldering: Printed circuit boards require soldering to assemble components. While for breadboards, components can be inserted into the terminal holes without soldering.

- Complexity: PCBs allow us to design complicated circuit that has precise routing and component layout, whereas breadboards are pretty limited in terms of the complexity, and are more suitable for basic circuit establishment.

- Reliability: Soldering for circuit boards ensures a secure and stable connections, whereas in some cases bread boards may have the issue of loose connection or intermittent contact.

- Usage Phase: Breadboards are normally utilized in the development phase and PCBs are used for the final electronic products.

- Current-Carrying Capacity: For carrying capacity, PCBs have better performance than breadboards. The current carrying capacity of breadboards is minimum as the components are connected by wires.

- Components Replacement: For breadboard, there are many designed slots, so the components can be easily plugged and changed. However,in PCB, the components are surface-mounted and/or through-hole mounted, which is hard to move and replace.

PCB and Breadboard: Their Advantages and Disadvantages

Now that we’ve explored the basic concepts of PCBs and breadboards, it’s important to understand the advantages and disadvantages of each:

The Advantages and Disadvantages of PCB

PCB has many advantages including reliability, durability and compact design, suitable for mass production and complex circuit design. Even more importantly, it has better signal integrity than breadboard.

However, it’s more expensive and takes longer time if you want to change things. When it is fabricated, the components and connections on the board become ‘permanent’, so any design changes necessitate the production of a new board.

The Advantages and Disadvantages of Breadboard

Conversely, breadboards are an excellent and flexible prototyping aid. In breadboards, the components can be inserted and removed without soldering. They are ideal for testing and experimenting with circuit designs. Additionally, breadboards are reusable and inexpensive, making it a good option for small sized projects, educational purposes, or low volume development.

This has the downside that they are not particularly durable, as connections can go loose with continued use. Breadboards suffer from signal integrity problems, especially in complex or high frequency circuits, and are inappropriate for compact or high density designs.

PCB Vs Breadboard: Which One You Should Use?

Since both PCB and breadboard have their own advantages and disadvantages, how do you decide which one is best for your project? It all depends on your needs and the project stage. Selecting the right option can make a great difference to the work and efficiency.

When to Use Breadboards?

If your project still at the early testing stage ore prototyping stage, you should choose the breadboard that allows you to experiment with circuit connections and make changes easily. Furthermore, breadboards are ideal for educational or hobbyist projects, or when prototyping a proof-of-concept circuit because they permit instant component placement and rearrangement.

When to Use Printed Circuit Boards?

PCBs, on the other hand, are essential when you’re ready to move from prototype to final product. Once you’ve confirmed your circuit design on a breadboard and ensured that it’s going to work, you should choose PCBs. A PCB is your go-to choice for applications requiring reliability, durability, and consistent performance, such as commercial electronic products, industrial equipment, or long-life devices

How to Turn Breadboards into PCBs?

For a breadboard design to be turned into a compact and reliable final product, there are several steps:

First, capture your circuit schematic in software like KiCAD or Eagle, representing all components and connections.

Second, use the PCB design software to arrange components layout and add copper traces. In this process, spacing and trace width must be considered to suit the design requirements.

Then, specify board details like layers, thickness, and any other special needs such as the high thermal resistance.

Last, use the design rule check (DRC) feature to catch issues before exporting Gerber files. And send your checked Gerber files to your PCB manufacturer so they can start to fabricate your boards.

UnityPCB is a reliable PCB manufacturer, which can fabricate and assemble your design to ensure it’s of a high quality. Our experience in the industry means that we can handle complex requirements with multi-layer boards, advanced materials and efficient, precise assembly.

Final Thoughts

When it comes to PCB vs breadboard, neither one has a definitive winner—each serves unique purposes with distinct advantages. PCBs are necessary for durable, long term applications and breadboards are perfect for quick prototyping and testing. In your case, the choice will depend on your project’s requirements. A breadboard can be very flexible if you’re experimenting with ideas or learning about circuits. A PCB is able to provide stability, better performance and professional results for a final, reliable product. By understanding their differences, you can confidently choose the right tool to bring your project from concept to reality.