Premium Surface Finish Options to Enhance Your PCB Performance

PCB surface finish is an important part of manufacturing process that applies a protective layer on the exposed copper traces and pads of the printed circuit board. This coating provides a barrier against oxidation and corrosion to the copper. It also increases solderability to ensure improved easy soldering during circuit board assembly. At UnityPCB we undertake range of PCB surface finish technologies such as HASL, ENIG, OSP, ENEPIG etc.

Hot air solder leveling is the method of spreading molten tin-lead solder on the surface of PCB through heating and using compressed air to level the solder so that it forms not only an anti-copper oxidation layer but also a layer with good weldability.![]() Pros: Excellent solderability, cost-effective, repairable

Pros: Excellent solderability, cost-effective, repairable![]() Cons: Unsuitable for fine-pitch components, not suitable for plated through-hole

Cons: Unsuitable for fine-pitch components, not suitable for plated through-hole

ENIG is a process where first a layer of nickel is plated on top of the copper surface and then gold is also plated. The nickel layer prevents diffusion of gold into silicon and the gold layer protects nickel and gives solderability.

![]() Pros: Excellent solderability, long shelf life, flat surface, good corrosion resistance

Pros: Excellent solderability, long shelf life, flat surface, good corrosion resistance![]() Cons: Higher cost compared to other finishes; possibility of variations in thickness of the plating

Cons: Higher cost compared to other finishes; possibility of variations in thickness of the plating

The OSP is used to form a thin layer of an organic skin film on the clean bare cooper surface and is resistant to anti-oxidation, heat shock and moisture, thus protecting the cooper surface from rusting (oxidation or vulcanization and the like) in the normal environment.

![]() Pros: Flat surface, environmentally friendly and lead-free, easy to rework and repair

Pros: Flat surface, environmentally friendly and lead-free, easy to rework and repair![]() Cons: Limited shelf life, careful handling is required

Cons: Limited shelf life, careful handling is required

ENEPIG is very much alike as ENIG in the fact that both use electro-less nickel over copper plating; the only difference of ENEPIG is that unlike the ENIG that has the gold deposited directly over the nickel, ENEPIG’s surface has palladium in between the nickel and the outer gold layer.

![]() Pros: Superior corrosion resistance, ideal for the fine-pitch devices and wire bonding application

Pros: Superior corrosion resistance, ideal for the fine-pitch devices and wire bonding application![]() Cons: It costs more compared to other types of finishing; complex and time-consuming

Cons: It costs more compared to other types of finishing; complex and time-consuming

Immersion silver is a surface treatment technology that deposits a thin layer of silver on the surface of the copper. The process gives a smooth, uniform and solderable surface.

![]() Pros: Budget-friendly , ideal for BGA and other small components, complies with RoHS standards

Pros: Budget-friendly , ideal for BGA and other small components, complies with RoHS standards![]() Cons: Sensitive to handling, not suitable for high-frequency applications

Cons: Sensitive to handling, not suitable for high-frequency applications

Immersion tin involves coating the copper surface with a layer of tin through a chemical reaction. This provides a flat and solderable surface.

![]() Pros: Economical, highly solderable, reworkable, RoHS compliant

Pros: Economical, highly solderable, reworkable, RoHS compliant![]() Cons: Oxidation possibility, whisker formation, unsuitable for PTH

Cons: Oxidation possibility, whisker formation, unsuitable for PTH

Based on your specific project requirements, our engineers would assist you in choosing the most suitable PCB surface finish type.

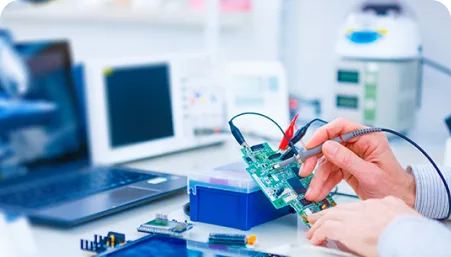

UnityPCB offers rapid prototyping services to streamline your product development cycle, ensuring quick and efficient progress.

We provide comprehensive testing services, from solderability evaluation, composition analysis, to corrosion resistance validation.

We offer a broad range of surface finishes like ENIG, ImAg, ImSn, OSP, and ENEPIG, tailored to meet diverse application needs.

Strict adherence to IPC and RoHS standards ensures top-quality, reliable, and durable PCBs that perform optimally in any application.

We have nearly 20 years of experience in PCB fabrication, specializing in different PCB surface treatment methods.

Committed to on-time delivery and exceptional customer support, we ensure responsive service from rapid prototyping to full-scale production.

This depends with the environment, application method, cost considerations, and the performance expectation of the final product. Temperature sensitivity, exposure to chemicals, requirement of solderability, and compliance with RoHS standards must be taken into consideration.

HASL offers way superior solderability and flatness and longer shelf life than ENIG. However, the HASL method is relatively cheaper as compared to other methods in simpler application.

The choice of the surface finish affects the reliability and longevity of the PCBs, better soldering qualities as well as giving the PCBs adequate guard against different environmental conditions.

Our quality assurances are effective and world-class; we use XRF analysis, solderability tests to confirm that the surface finish has met defined requirements.

Absolutely. As a team of professionals with many years of experience in PCB industry, we are capable of advising on the best surface finish based on your specifications.

YES. Our surface finishes are RoHS and lead-free compliant for environmental regulations.

Contact Us