UnityPCB: Ensuring Quality Excellence in Every PCB & PCBA

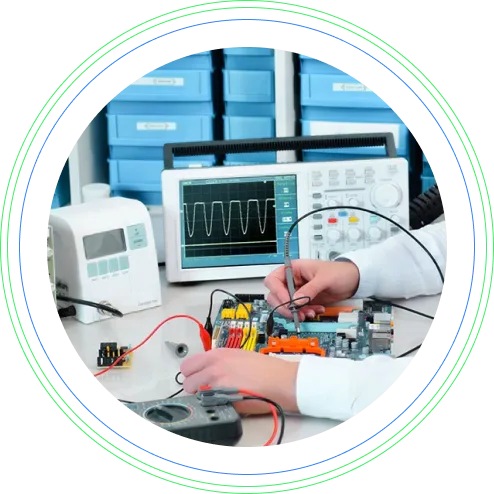

The PCB Quality Control involves a thorough inspection of bare boards for such flaws as Copper Traces, solder mask & Silkscreen, board size, and hole diameter. In PCBA we concentrate on fine placement accuracy of components, quality of solder joints and very strict functional test on printed circuit board assemblies. Such an approach ensures that each product that is produced in our facility is of the highest quality and with high reliability.

01

Our engineers double check Gerber files to ascertain whether or not they meet the required design and their implementation practicality.

02

We cooperate with well-known material suppliers, such as Shengyi and Rogers, and all the incoming materials are checked for international standards.

03

We employ the best equipment to get the best results in the production of the PCB. We are equipped with LDI machines, precision etching equipment, silkscreen printing, and many others.

04

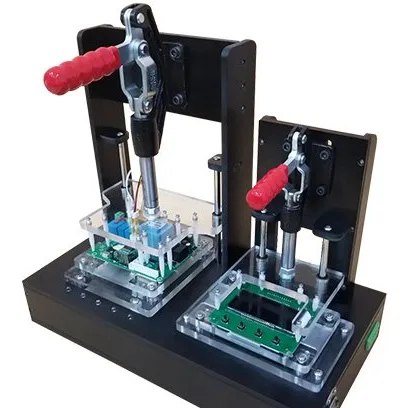

Following ISO9001:2015 and IPC guidelines, we perform various testing methods such as visual inspection, flying probe testing, and Automated Optical Inspection.

01

Our engineers double check Gerber files to ascertain whether or not they meet the required design and their implementation practicality.

02

Our team checks the amount of solder paste and its uniformity before the placing of the components to get the required soldering performance.

03

Concerning AOI, we conduct online AOI right after reflow soldering has been completed. Also, we perform off-line AOI to check the quality against IPC-610D to enhance the overall quality of the PCBs.

04

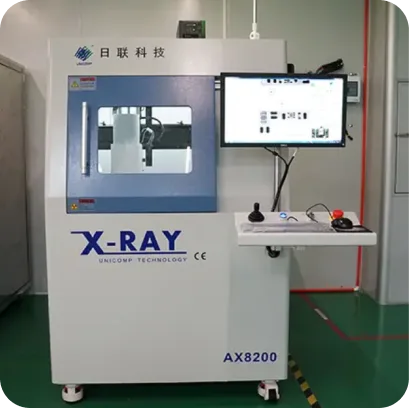

X-Ray inspection is employed to examine hidden solder joints especially those of BGA parts. We also do a first sample test to confirm on component values and their position on the board.

05

The existing QC personnel do a visual inspection according to the IPC-610 guidelines. This final process guarantees that all products produced are perfect before they are shipped to the customers.

UnityPCB adheres to IPC-A-600, IPC-A-610, ISO 9001:2015, and IPC J-STD-001 standards. We hold ISO 9001:2015 certification, employ an IPC Certified Trainer, and maintain UL Recognition and RoHS compliance, ensuring top-quality PCB manufacturing and assembly.

Using high resolution cameras to detect visual defects in components and solder joints. This method is efficient in detecting problems such as misalignments, missing parts, or solder problems.

This approach helps confirm the electrical continuity of the printed circuit boards together with the isolation between them. It identifies shorts, opens, and wrong connections.

It uses moving probes to check electrical characteristics of boards, suitable for prototype or low batch production. And it is easier to change the test program compared to using costly fixtures.

This technique uses X-rays to visualize interior of the PCB, mainly used in multilayer and BGA assemblies. It shows defects like voids in the solder joints, inside shorts, and misalignment, etc.

This testing measures the performance of the PCBA regarding its planned functions. It checks if the assembled board performs the intended functions and operates correctly in various working modes.

Our professional team has accumulated many years of experience in the PCB industry and provides first-class quality control for your PCB and PCBA projects.

We are equipped with the most advanced inspection equipment to provide customers with efficient quality control services and ensure the accuracy and reliability of testing.

Our quality control process covers all aspects, from the initial incoming material inspection to the final functional test, ensuring the high quality of our products.

At UnityPCB, we operate with state-of-the-art technology to ensure that the quality we offer is exceptional. High-quality equipment means accuracy, speed, and dependability at various stages of manufacturing and testing.

Contact Us