Quality Control

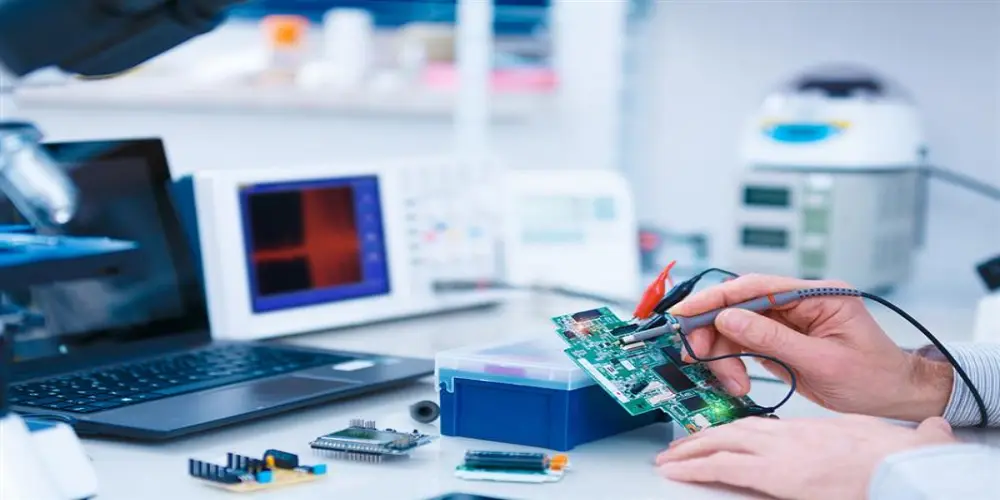

PCB functional testing is a critical procedure carried out in the PCB assembly process to ensure the board’s functionality and performance as per the design specifications. We perform this testing method to ensure the reliability and performance of the circuit boards before they are deployed. This article will give an overview of what actually PCB functional testing is, how it operates, and the techniques, advantages, and disadvantages of PCB functional testing.

PCB functional testing, also known as functional circuit test (FCT), is performed on a fully assembled PCB to assess its functionality as well as its operational efficiency. This testing method entails applying power on the PCB and putting it through a series of electrical tests and operating conditions that are typical to examine if all the components and connections function as expected and meet specified design requirements. Since it assesses the PCB’s actual working under normal operating conditions, functional testing can detect the existing flaws, errors, or inconsistencies that might not be visible to the naked eye or other forms of testing; thus guaranteeing the proper functioning of the PCB before it is incorporated into the end-product.

PCBA functional test involves below key processes, including: 1.Decide which function to test. 2.Generate input data in light of the PCB’s functional specifications. 3.Apply the function specifications of the PCB to make expectations of the data that ought to be delivered. 4.Perform the test by replicating the actual PCB environment. This included using a device that communicates with the PCB and supplies it with the right power and signals. Record all output for analysis and verify if the PCB performs as required. 5.Compare the actual data that has been generated from the output of the PCB with the expected data in terms of these specifications.

• Identifies Functional Defects: PCB Functional Testing confirms that the board provides the intended functionality and reveals problems like incorrect values of components, connection problems, or software errors.

• Enhances Product Reliability: As it reproduces the real use conditions, FCT assists in checking the overall dependability and performance of the PCB, thus minimizing the opportunities for failure during operation.

• Reduces Production Costs: It is important to detect the defects in the early stage of testing rather than waiting until the product is assembled, to reduce the amounts needed for rework, repair, or replacement that raises production costs.

• Speeds Up Time to Market: Since PCB functional testing detects problems at the early phase, there is no need for multiple testing iterations; thus, products are developed and released faster.

• Power Supply Problems: Functional circuit tests can identify problems such as a drop in voltage, currents leaks, and power distribution problems.

• Signal Integrity Issues: This testing method can identify signal quality issues including noise, crosstalk, and signal attenuation.

• Incorrect Component Values: FCT can also identify incorrect value of a resistor, capacitor, or indicator.

• Faulty Connections: It detects faulty wiring such as an open circuit, a short circuit, or a poor soldering joint.

• Incorrect Component Placement: The test can identify components which are missing or connected in the wrong orientation.

• Defective Components: It checks defective parts like damaged Integrated Circuits, Capacitors or Transistors that do not perform their intended operation.

1. Test Procedure Planning

Testing the PCB by cataloging components and methods. This method guarantees that all the parts are well tested. For example: Resistors – With the help of the multimeter the actual figures of the resistance present in the circuit must be questioned against figures which have been put down in the design on paper. Sensors – Find out signals and check electrical output in order to make sure that the sensors are functioning correctly. Capacitors- How capacitors work, measure capacitance, and confirm charging and discharging.

2. Voltage Testing

In this technique, the technicians use voltmeter to confirm the voltage value at every node of the PCB, which verifies that the board is supplying the required power as laid down in the design of the circuit. Additionally, initial power-on tests are conducted to further confirm appropriate beginning functionality.

3. Load Testing

In Load Testing, we are able to see the design margin’s possible failures. Technicians replicate actual operating loads and environment to evaluate the PCB’s operational boundaries, including: Temperature – Test functionality in extremes temperatures as to check the equipment’s reliability. Current – Gradually raise the current through it to determine the value of the capacity. Frequency – Change clock speed to cover the whole range and check the interferences of resonance type.

4.Quality Control Testing

QC testing helps to de-risk when releasing products to the market. The last step of validation confirms that the PCB complies with all specification and requirements of a quality product in the market. Common checks include: Automated Optical Inspection – An instrumentation that can identify defects in solder, component, etc. Design Rule Checking – This ensures that products are manufacturable and also checks on the reliability aspect of a product. The Regulatory Testing ascertains the company’s adherence to certification (UL, CE etc. ).

• Complex Test Setup: In PCB functional testing, complex equipment, specific test fixtures, and software are needed to perform the necessary tests, and all this involves a lot of time and money.

• High Initial Costs: The cost of inventing test fixtures, procuring the test equipment and developing a set test program is relatively high, especially for low run volumes and prototypes.

• Time-Consuming for High Volume Production: As for drawbacks, functional testing can be rather time-consuming as compared to other approaches and thus slow done the production rates in high-turnaround manufacturing lines.

• Customization Requirements: Each PCB design may need its test fixture and program, which significantly raises customization demands and testing time.

It can discover wrong component values, faulty joints, defective parts, firmware bugs, timing issues, power issues, and many others.

ICT(In-Circuit Testing) inspects each connection and component on an individual basis in the PCB while FCT tests the functionality of a powered-up PCB by simulating real working conditions.

Yes, it is possible to automate Functional Testing using specialized test systems.

Typically, PCB Functional Testing involves using test fixtures, special test instruments such as oscilloscopes, multimeters, signal generational facilities and custom software.

Yes, UnityPCB can do particular Functional Testing setups for your specific project needs, which contains the development of special test fixtures and programs according to the functionality of your PCB.

Functional Testing at UnityPCB is done by following the IPC and ISO standards to meet defined quality and standards.

In case a PCB is NOT pass through the Functional Testing, UnityPCB’s Engineers team will analyze failure, determine causes, and provide a solution to address the problem in the shortest time.

Yes, UnityPCB can do particular Functional Testing setups for your specific project needs, which contains the development of special test fixtures and programs according to the functionality of your PCB.

Elevate Your PCB Quality with UnityPCB's Rigorous Testing Solutions

Contact Us