From prototyping to mass production, our cutting-edge facilities are equipped to handle all your PCB requirements.

At UnityPCB, we excel in comprehensive PCB fabrication services, from high-density interconnect and rigid-flex boards to multilayer PCBs and specialized medical PCBs. Our advanced facilities, stringent quality standards, and value-added services like assembly and testing ensure exceptional reliability and efficiency in every project.

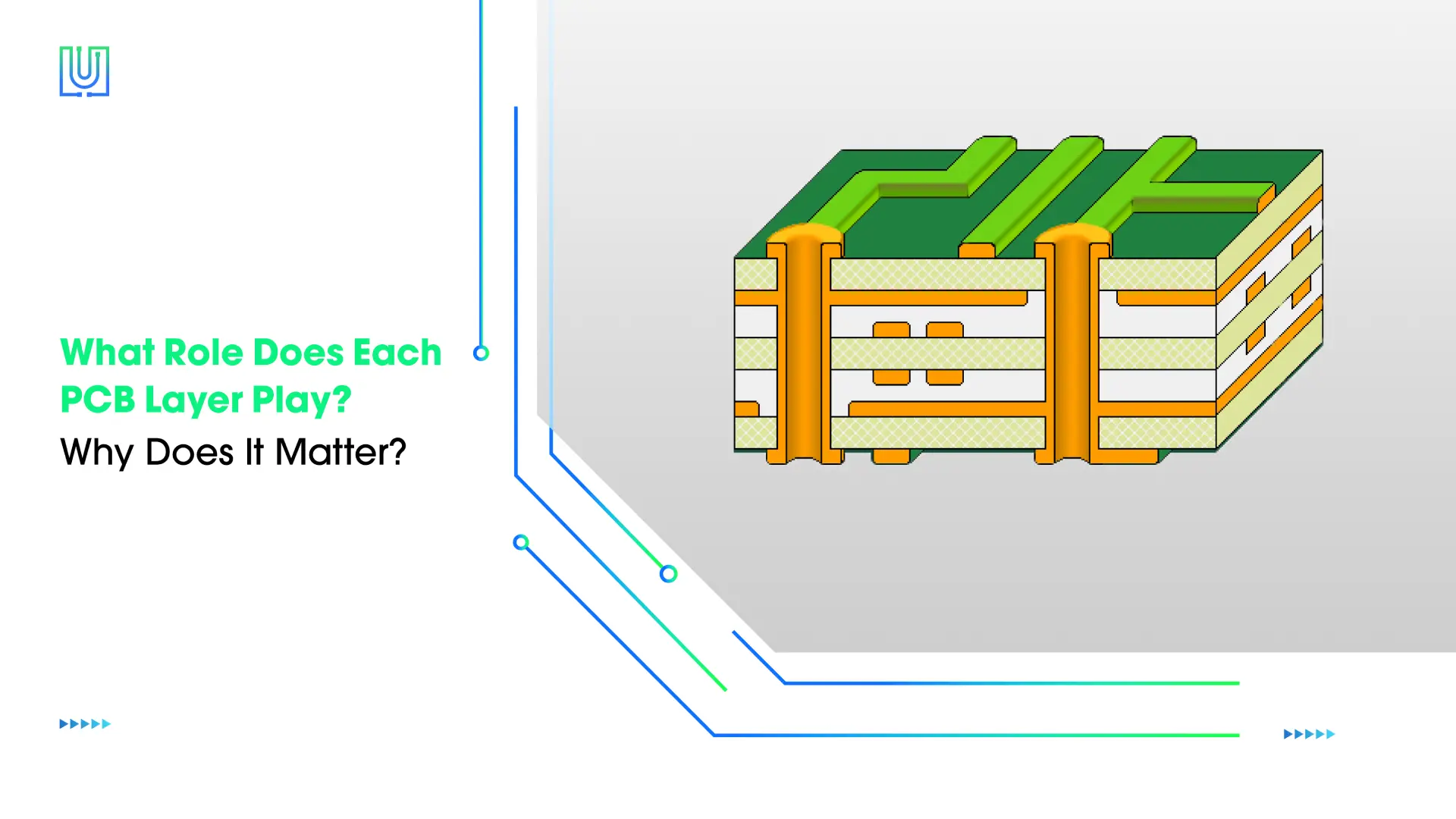

| PCB layers: | 1-18 layers | |

| Board materials: | FR-4, FR-5, CEM-1, CEM-3, RCC, metal, ceramic... | |

| Max. board size: | Up to 570*1200mm | |

| Min. board size: | 10*10mm | |

| PCB thickness: | 0.8mm,1.0mm,1.2mm,1.6mm...(based on different layers) | |

| Mini trace width: | 4mil | |

| PCB via diameter: | 0.15mm-2.5mm | |

| Outer layer copper thickness: | 0.5-5 OZ | |

| Inner layer copper thickness: | 0.5-2 OZ | |

| Min. BGA pad size: | 7mil | |

| Through-hole copper thickness: | 25um | |

| Buried& blind vias copper thickness: | 20um | |

| Surface finish: | HALS/HALS lead free, ENIG, ENEPIG, OSP, I-Sn, I-Ag |

UnityPCB commits to the highest standards of PCB production, using state-of-the-art testing and quality control measures to ensure each board delivers exceptional performance and reliability.

From simple single-layer boards to complex multi-layer designs, UnityPCB has the capability to handle a broad spectrum of PCB requirements, making it a one-stop solution for all your PCB needs.

UnityPCB uses only the best materials, including advanced substrates and conductive inks, which enhance the durability and functionality of the PCBs, suitable for demanding applications across various industries.

With sophisticated manufacturing processes and meticulous attention to detail, UnityPCB ensures that every PCB meets precise specifications, providing consistent results that our customers can depend on.

UnityPCB’s 12,400㎡ facility includes a 2,600㎡ clean room, 5 SMT lines, and 3 DIP production lines. Equipped with precision drilling machines, plating systems, and etching setups for exact circuit patterning, as well as reflow soldering machines and wave soldering systems. Our state-of-the-art X-Ray and AOI machines ensure the high-quality PCB production.

UnityPCB specializes in a wide range of PCB types including Single-Sided, Double-Sided, Multilayer, Flexible, Rigid, Rigid-Flex, HDI PCBs, and so on.

The PCB fabrication process involves preparing design files, etching copper to form circuits, drilling holes, plating, applying a solder mask, adding a surface finish, and performing final inspections to ensure quality.

Common materials include FR4 (fiberglass epoxy laminate), aluminum, ceramic, and high-frequency laminates.

Certainly, we provide prototyping services to allow you to thoroughly test and validate your PCB designs before moving into mass production runs.

You can easily obtain a quote by submitting your PCB specifications through our website’s quote request form. Or just click here to send your inquiries directly to our experts, we will respond within 24 hours.

We kindly request that you export your files in the industry-standard Gerber RS-274X and NC Drill formats. Please compress all the necessary files, including a readme file, into a single ZIP archive before sending them over to us.

Yes, in addition to PCB fabrication, we offer comprehensive PCB assembly services, including component sourcing, automated and manual assembly processes, and functional testing.

We are ISO 9001 certified, and our quality control processes include automated optical inspections (AOI), electrical testing, and rigorous physical inspections at multiple stages of the manufacturing process.

Absolutely! Our facilities are equipped to handle high-volume production runs while maintaining consistent quality and reliability.

The typical lead time varies depending on the complexity and quantity of the order. Standard lead times are 1-2 weeks, but expedited options are available if you need your PCBs faster.

LGA vs BGA, which package you should use for your PCB? Both of them play a key role in connecting integrated circuits and circuit boards,

In the PCB assembly process, dust, flux residues, and other debris can accumulate on circuit boards. These contaminants accumulate, leading to circuit board malfunctions or

When you need to choose a circuit board, you have many options. From basic rigid boards to sophisticated flexible boards, from straightforward single-layer boards to

Contact Us