LED PCB is becoming the mainstream choice for lighting. This kind of PCB features better lighting effects and a longer service life with less energy consumption than traditional light sources. It also shows unique advantages in many fields like display screens, traffic lights, plant growth lights, etc. Here, we will provide you with a guide to different types of LED PCBs, their benefits as well as their applications.

What Is LED PCB?

Light-emitting diodes, or LEDs use current flowing through their chips to emit light. LED PCB (LED Printed Circuit Board) is a circuit board designed specifically for LED components. Since LED generates a lot of heat when working, LED circuit board usually uses materials with good thermal conductivity to help dissipate heat effectively. Currently, surface mount packaging is the most commonly used LED packaging method. A single LED component’s brightness is typically constrained. In practical applications, multiple LED components are integrated into the circuit board to achieve the desired brightness.

Common Types of LED PCB

LED circuit board is a circuit board designed for mounting LEDs. The substrate material of the board determines the PCB thermal conductivity. Below we will introduce 6 types of PCBs based on different substrate materials.

Aluminum LED PCB

Aluminum LED printed circuit board is a common and cost-effective kind of circuit board. This kind of LED circuit board has excellent thermal conductivity. In high-power LED lighting applications, aluminum substrates can effectively extend the life of LED chips. It is especially suitable for plant growth light applications.

Copper-base LED PCB

Copper-based LED printed circuit board has higher thermal conductivity than aluminum-based LED circuit board and is more conducive to heat dissipation. This kind of LED circuit board can be used in high-power LED lamps, such as car headlights.

FR-4 LED PCB

FR-4 LED printed circuit board is an ideal choice for daily home lighting or low-power lighting, where the heat dissipation requirement is not high. It is lightweight, inexpensive, and simple to process.

Ceramic LED PCB

Aluminum nitride and aluminum oxide are two common ceramic materials used in ceramic LED printed circuit boards. Ceramic LED circuit boards are often used in photography and swimming pool lights.

Hybrid Substrate LED PCB

Hybrid LED printed circuit boards can have two or more substrate materials. Different substrate materials are combined together to increase the flexibility of the PCB and achieve the best performance.

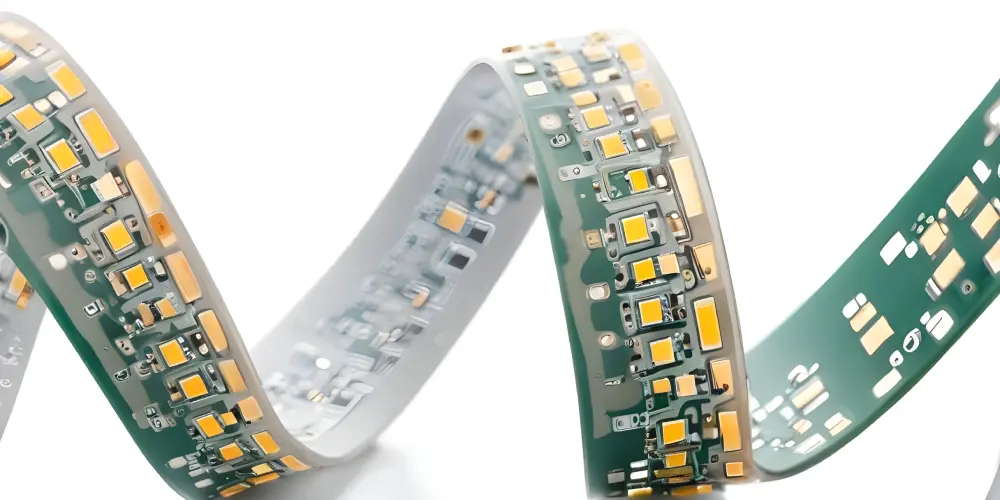

Flexible LED PCB

Flexible LED printed circuit board uses polyimide or polyester as substrate material, which can realize lamp designs with various curvatures. It is often used in mask lights and decorative light strips for indoor or outdoor use.

Why Are Aluminum LED Circuit Boards So Popular?

Common aluminum PCBs include flexible aluminum, hybrid aluminum, and multi-layer aluminum circuit boards. It is popularly used in LED circuit boards because of the following advantages.

- Aluminum is an abundant material available on earth.Compared to other metal-core circuit boards, aluminum LED circuit boards are significantly less expensive. It is a cost-effective LED circuit board with high-capacity heat dissipation.

- Aluminum is a recyclable and non-toxic material. When their useful life is up, they may be safely disposed of or recycled.This provides a complete environmental solution for the lighting industry, truly realizing green lighting.

- Aluminum has excellent stability and can maintain its shape even in high-temperature environments, which effectively prevents circuit board deformation and component damage. This type of PCB is an ideal choice for industrial lighting and automotive lighting.

The Benefits of LED Printed Circuit Board

LED PCB is increasingly popular in many industries. Below we will introduce some benefits of LED PCB, and you will know why it is popular.

Decreased Power Consumption

The significant advantage of LED PCB lighting is low power consumption. Compared with traditional light bulbs, it can reduce energy consumption by at least 75%.

Greater Service Life

The lifespan of LED lamps is approximately 25,000 hours, which is five times that of incandescent bulbs. As a result, you will save time, money, and energy by not having to buy and replace bulbs as frequently.

Space-saving

LED PCB can save space due to its compactness. LED can be integrated into the circuit board to achieve high compactness and does not require complex circuits. Therefore, LED PCBs can perfectly adapt to the requirements of various application scenarios. This feature allows LED circuit boards to be flexibly used in small electronic devices such as mobile phones and computer lights, as well as large systems such as automotive lighting and traffic lights.

Environmental Friendliness

Unlike other bulbs, LED PCB doesn’t contain mercury. Especially the aluminum LED circuit board, which can also be recycled. It is easier to handle and safer. LED lights use less energy than other types of bulbs and last longer, resulting in less waste.

Radiofrequency-free

The LED circuit board doesn’t emit radio frequencies. It will not interfere with surrounding electronic devices and components.

Challenges Faced in LED Circuit Board

The design of LED circuit boards faces key challenges related to temperature control. The issues to be focused on to achieve efficient and stable LED circuit boards are the following.

Thermal Management

LEDs generate heat during operation. If this heat cannot be efficiently dissipated away, the temperature of the circuit board will rise and have an effect on the product’s performance.

Lighting Color

LED PCB color performance is directly impacted by temperature. To maintain LED light color stability, the operating temperature of the PCB has to be strictly controlled.

Lifespan of the Light

LED circuit board is famous and widely used because of their long service life. While temperature heavily affects its lifespan.

Key Industry Applications for LED PCB

The use of LED PCBs is growing continuously. In addition to replacing light bulbs for lighting, you can see its application in various industries. Let’s take a look at the applications of LED circuit boards in several industries.

Consumer Lighting

In the field of consumer lighting, LED PCB fully demonstrates its important position and wide range of uses. LED circuit board is everywhere, such as flashlights, table lamps, spotlights in our daily lives, LED growth lamps for agricultural planting, stage lights in theaters, etc. These lighting equipment use LED PCBs, which can provide excellent lighting effects and have the advantages of durability and high energy efficiency.

Consumer Electronics

Consumer electronics such as computers, mobile phones, and televisions usually use LED displays. These consumer electronic devices are very sensitive to heat, so aluminum LED circuit boards are favored in this field due to their excellent thermal conductivity.

Medical

LED PCBs are extensively utilized in a variety of medical equipment. These medical devices usually use high-power LED circuit boards and aluminum LED circuit boards. Small flashlights can help doctors check external parts of the body such as the ears and nose. They can also be used as diagnostic tools to check the inside of the body. Endoscopic cameras can use LED light sources to provide sufficient illumination to help the camera capture high-definition images. LED lights on operating tables can provide enough light for surgery. Aluminum LED circuit boards can also be used in medical scanning equipment.

Transportation and Automotive

In automobiles, LED circuit boards are widely used in indicator lights, brake lights, headlights, etc. LEDs can improve lighting effects, reduce manufacturing costs, and make maintenance easier. Interior and dashboard lights can also provide various brightness and color settings. In the field of transportation, LED PCBs are often used in traffic lights, highway tunnel lighting, and street lighting. LED circuit boards have become an indispensable part of modern transportation due to their excellent performance and cost advantages.

Choosing UnityPCB as Your Ideal LED PCB Manufacturer

UnityPCB has been in the LED PCB field for nearly 20 years, specializing in PCB design, manufacturing, and assembly services. We provide one-stop service and emphasize high quality and reliability. Our primary priority is to offer our customers exceptional products that fulfill industry standards. The production procedure complies with IPC, ISO 14001, ISO 9001:2015, etc. Don’t hesitate to quote us, and we will reply promptly.