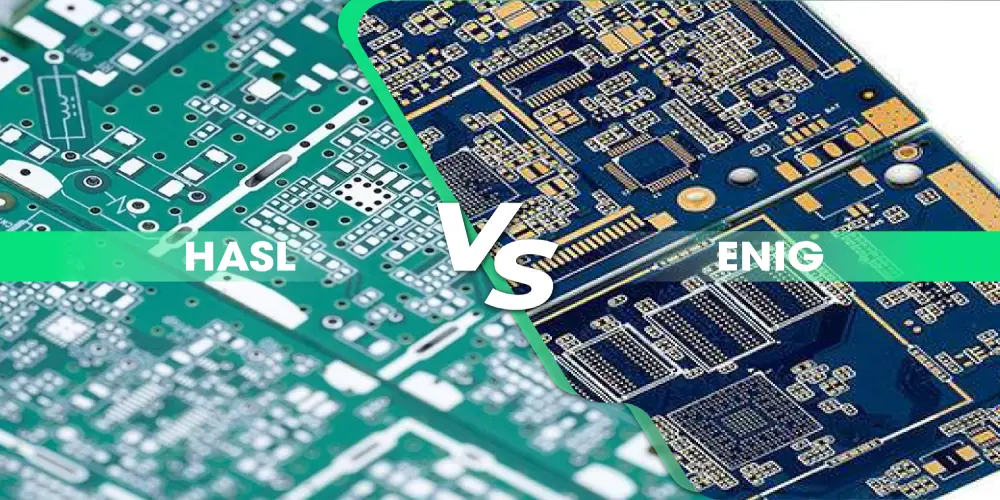

PCB surface finish is the coating applied on exposed copper pads and traces to protect them from oxidation and improve solderability. HASL vs ENIG are two common PCB surface finishes, each offering distinct benefits tailored to different needs. When selecting the optimal PCB surface finish, consider some of the most important factors like performance, reliability, and durability and make sure the circuit board will function effectively in its intended working environment. In this blog, we will give a detailed comparison of HASL vs ENIG to help you make an informed choice.

An Overview of HASL vs ENIG

What Is HASL?

HASL (Hot Air Solder Leveling) is a cost-effective and widely used PCB surface finish. In this process, the PCB is immersed in a molten solder bath to form a solder coating on the exposed copper. A compressed hot air knife is then used to remove the excess solder, providing a flat surface. HASL can be classified into two types: lead-based HASL and lead-free HASL.

What Is ENIG?

ENIG (Electroless Nickel Immersion Gold ) is a double-layer metal coating composed of an electroless nickel base layer and a thin immersion gold top layer. The nickel layer serves as a protective barrier for the exposed copper while providing a surface for the gold layer. The gold layer provides a great solderable surface and stops the nickel from oxidizing.

One of the outstanding features of ENIG is its ability to form a very flat and uniform surface, making it ideal for precise BGA component installation. Though ENIG may suffer from “black pad” defects, its excellent surface flatness and environmental compliance make it an increasingly popular PCB surface treatment choice.

HASL vs ENIG: Key Differences Revealed

Below is a complete comparison chart displaying the differences between HASL vs ENIG to make a better choice.

| Aspect | HASL | ENIG |

| Surface Flatness | An uneven surface. | Flat and uniform surface. |

| Composition | Tin-lead (or lead-free) coating. | Gold over nickel. |

| Solderability and Reliability | Good solderability. | Excellent solderability. |

| Copper Adhesion | Good adhesion, but uneven surface can affect bonding. | Strong adhesion. |

| Cost | Lower. | Higher. |

| Coating Thickness | Relatively thick. | Thin coating. |

| RoHS Compliance | Lead-based HASL does not comply with RoHS, while lead-free HASL complies. | Fully RoHS-compliant when gold over nickel is used. |

| Shelf Life | Shorter shelf life due to sensitivity to oxidation. | Longer shelf life, as it resists oxidation. |

| Electrical Properties | Good, but oxidation can lead to poor performance over time. | Excellent electrical conductivity with a gold coating. |

| Thermal Stress | Higher thermal stress. | Lower thermal stress. |

| Signal Integrity

| Surface unevenness can cause impedance variations, affecting signal integrity. | Providing an even surface that minimizes impedance variations. |

| Compatibility | Not ideal for fine-pitch SMD components. | Highly compatible with fine-pitch SMD components. |

| Application | Generally employed in consumer devices that are not exposed to harsh environments. | Utilized in high-performance applications such as medical equipment, aerospace, and telecommunications. |

Pros and Cons of HASL and ENIG

Pros of HASL

- Affordable Cost: HASL is one of the most affordable PCB surface finishes for circuit boards, with a relatively simple production process and low material costs. It is much cheaper than ENIG, making it particularly suitable for budget-conscious projects or high-volume production.

- Good Solderability: The surface provides good solderability, and that makes it easy to form reliable solder joints. HASL is compatible with hand soldering, reflow soldering, and wave soldering.

- Mature Technique: It is a proven and well-established technology in the PCB industry, and most PCB manufacturers have extensive experience with the process.

Cons of HASL

- Uneven Surface: HASL provides an uneven surface, which is not desirable for BGA devices and fine-pitch components. It is also not ideal for SMT assembly, where a flat surface is essential for accurate solder joint formation.

- Oxidation Over Time: While the PCB surface finish is protective at first, it may be prone to oxidation.

- Thermal Stress: The process involves immersion of the PCB in a high-temperature molten solder bath that can lead to potential issues such as warping or delamination of the heat-sensitive materials.

- RoHS Compliant: Lead-based HASL includes hazardous materials (lead) that are bad for the environment and don’t meet RoHS

Pros of ENIG

- Exceptional Surface Flatness: ENIG provides an excellent flat surface, making it a popular choice for precise component placement such as fine-pitch components and ball-grid arrays.

- Excellent Solderability: The top gold layer offers outstanding solderability, even after extended storage.

- RoHS Compliance: ENIG is a lead-free surface finish, and it is fully RoHS compliant.

Cons of ENIG

- Black Pad Defects: The black pad may result from excessive phosphorus causing corrosion between the nickel and gold layers due to improper chemical treatment or process control. This can cause failure of the solder joint and open circuits, affecting the PCB’s reliability and performance. Black pad defect can be reduced through effective process control, but it is still a concern for some PCB manufacturers.

- Higher Cost: The technique uses expensive materials (gold and nickel) and involves complex manufacturing processes, which both increase the overall production cost.

- Difficult to Rework: The nickel layer can corrode when exposed to high temperatures during rework or repair.

HASL vs ENIG: Which Should You Choose?

Choosing between HASL vs ENIG depends on the project requirements and budget constraints. HASL is suitable for low-budget projects or when the PCB surface flatness is not critical. ENIG is suitable for high-performance PCBs as it provides a flat surface, excellent solderability, and oxidation resistance to ensure that the PCB works under harsh conditions. At the same time, its higher cost and complex process, including risks such as black pad defects, also need to be balanced with consideration. When making the final decision, you need to consider multiple key factors and make the best choice after trading them.