Quality Control

The process of producing a printed circuit board involves a significant testing phase. Every PCB should undergo testing so that the manufacturer is able to identify electrical or circuit problems before dispatching the PCB. When it comes to all kinds of testing techniques, the Flying Probe Test(FPT) is recognized as one of the most efficient ones. At UnityPCB, we leverage this technology to ensure that all our printed circuit boards are of the best quality by the time we deliver them to the market.

The term flying probe testing refers to a PCB testing technique that employs probes that “fly” over the circuit board for contact with several test points at the same time. A flying probe tester uses one or more test probes, which contact the test points at the top and bottom of the PCB. They then transfer from one position to another on the circuit board in order to test a number of conductors or components. They operate with the instructions of the program, which outline the board that is to be tested. These machines are equipped with highly precise needles to detect if the PCB is working properly and in order. These systems do not necessitate any test fixturing or custom tools. This makes flying probe testing a cost-effective option for boards in their initial stages of development. In addition, FPT is also suitable for low to mid-volume production runs.

Some of the common issues that can be identified through flying probe testing include:

Open Circuits: The test can determine if there is a break of the conductive path and therefore ensure that all connections are intact.

Short Circuits: They point at unwanted connections of various conductive paths that may lead to certain dysfunctions.

Component Placement Errors: The test works to verify if all of the components are placed correctly and if their orientation is correct.

Incorrect Component Values: It confirms that all the components like the resistor, capacitor, and others have been placed in the correct values that are required by the designs.

Soldering Defects: The test can detect poor solder joints such as cold solder joints which at worst give intermittent connections or failures.

Flying probe testing is a quite simple procedure that can be broken down into three main phases:

Step 1: Test Program Creation

The initial step is to create a test program for flying probe testing. This is generally done in an offline PC with appropriate software being applied. To create an effective test program, you’ll need to input the following data:

Gerber files

A detailed bill of materials (BOM), preferably in Excel format

Electrical computer-aided design (ECAD) files in CAD format

Phase 2: Board Preparation and Loading

When the test program is ready, the circuit board is put upon the tester’s conveyor belt. The belt takes the board to the testing area where the probes will work in their capacity as tests. This may involve testing one board at a time, up to several boards at a time depending on the program settings that have been set.

Phase 3: Testing and Analysis

In this last stage, the probes scan the circuit board based on the test program that has been set down. On board, they apply test signals to carry out electrical and functional checks on the board at different points. The obtained measurements are then analyzed or processed to know whether each of the circuit sections meets the required specifications.

If any part of the board does not produce the expected outcome or differs from the programmed values, the probes will indicate a defect, thereby indicating that the unit has not passed the test.

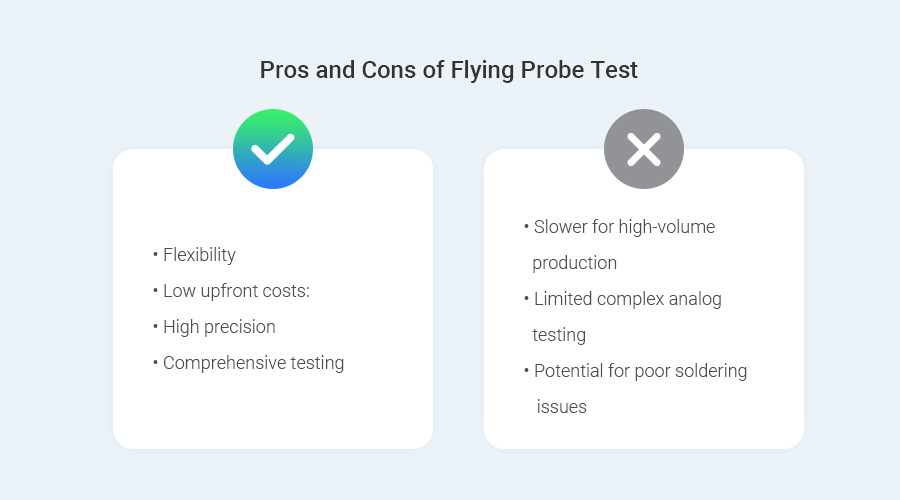

• Flexibility: One major advantage of flying probe test is that it can be used for almost any given design of PCB as there is no requirement for the creation of test fixtures.

• Low upfront costs: Compared to other testing strategies, the amount of money spent at the beginning to perform this testing method is rather low, in essence, no custom test fixtures are required. Thus, it is an economical option for prototypes and small to medium-batch production.

• High precision: Flying probe test is a precise and reliable PCB testing method. The probes are capable of reaching into fine pin pitch components and densely populated boards

• Comprehensive testing: One of the key advantages of the flying probe test is that it can do almost all types of electrical tests, hence enabling it to be a comprehensive tool in confirming the functionality of the PCBs.

While the flying probe test is highly versatile, it does have some limitations:

• Slower for high-volume production: Flying probe test is not suitable for high-volume production, which is slower than in-circuit testing (ICT). This is because an ICT system uses a fixed bed-of-nails fixture that can test multiple points simultaneously.

• Limited complex analog testing: While suitable for most digital and basic analog tests, FPT may struggle with complex analog circuit validation.

• Potential for poor soldering issues: In some circumstances, making probe contact with component leads can cause loose connection or poor soldering.

Not exactly. Though flying prob testing is appropriate for different PCBs, especially the prototypes, small amounts, and frequently modifying ones, it is not suitable for high-volume production or extremely complex boards.

When it comes to flexibility and cost-effectiveness, flying probe testing is a better choice than in-circuit testing. However, ICT is more suitable for large production thanks to its higher testing speed.

Despite the flying probe test’s versatility and ability to identify many electrical failings, it is notable that not all sorts of issues can be detected, especially mechanical defects. It is normally combined with other testing techniques to ensure comprehensive coverage.

Yes, the Flying Probe Testing technique can be as effectively used on the double-sided PCBs. The probes can go to both sides of the board to perform tests.

Products that are still in the prototype, have low-volume production or may go for frequent design modifications benefit most from this testing method.

Elevate Your PCB Quality with UnityPCB's Rigorous Testing Solutions

Contact Us