Today, BGA packages have been widely used in electronic products of all sorts, such as smartphones and high performance servers, especially for high-density integrated circuits. They gain wide popularity because of their dense pin layout together with superior thermal and electrical performance. This article discusses 7 fundamental BGA package types, which details their key characteristics and optimal usage scenarios with added advantages.

What Is a BGA Package?

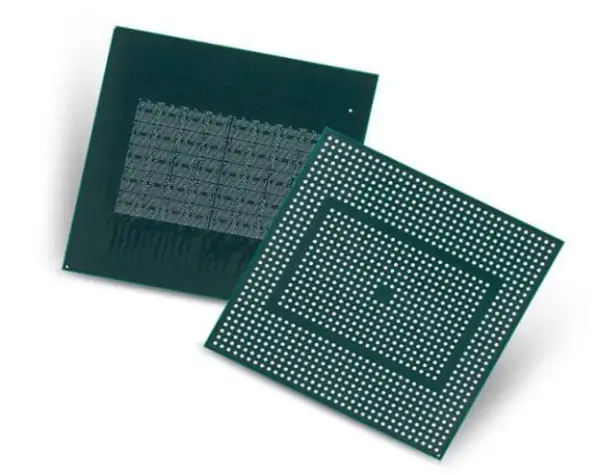

Ball Grid Array (BGA) package is a kind of surface mount packaging. But unlike the traditional leaded packages, where the pins are located on edges of a chip and soldered to the PCB, BGA uses an array solder balls on the bottom surface of a chip that connects to the PCB. Above all, this method maximizes the connection density and simultaneously allows for more compact and efficient design.

7 Most Common BGA Package Types

All BGA packages are designed in the same basic manner, but there are other varieties to satisfy specific requirements. In the following, we will introduce 7 common types of BGA packages:

PBGA (Plastic Ball Grid Array):

The Plastic Ball Grid Array or simply known as PBGA is invented by Motorola, and then and adopted by other manufactures in the industry. It consists of bismaleimide triazine (BT) resin as the substrate material. This BGA package type is regarded as the first choice for double-sided PCBs, also commonly used in everyday consumer electronics such as smartphones and tablets as well as in different computing systems.

CBGA (Ceramic Ball Grid Array):

Ceramic BGA has characteristic 10:90 tin to lead solder ball composition. The melting temperature of these packages is elevated, which necessitates the use of the C4 (Controlled Collapse Chip Connection) method in order to connect the BGA packages with the printed circuit board. Though CBGAs come at a premium over plastic BGAs, they provide much better reliability in terms of improved electrical performance and heat dissipation capabilities.

TBGA (Tape Ball Grid Array):

A Tape Ball Grid Array (TBGA) package has a flexible substrate that is made of polyimide tape to support the semiconductor chip. Compared with standard BGAs, it offers improved electrical performance as well as thermal management. Its adaptable structure decreases pressure on solder joins which leads to improved durability and performs best in temperature-varying applications. TBGA’s tight size and slim form enable use in portable electronic devices including cell phones laptops and digital imaging equipment.

FBGA (Fine-pitch Ball Grid Array)

The Fine Pitch Ball Grid Array is a smaller and denser variation of the regular BGA package. The near chip-scale design allows FBGAs to have thinner dimensions along with reduced body size compared to traditional BGAs. A tight ball pitch is the distinctive feature of Fine Pitch Ball Grid Array which means that the solder balls are placed closer together. FBGAs provide special value in portable electronics and smart wearable devices because of their minimal size usage and high-performance capabilities.

FC-BGA (Flip Chip Ball Grid Array):

The FC-BGA integrates flip-chip technology or a controlled collapse chip connection. It has Ceramic BGA-like structure using BT resin in place of ceramic substrate at a lower price. In addition, this type of BGA package has better electrical performance since it reduces the length of internal circuit pathways. Therefore, FCBGA is a preferred choice for high performance applications, and it is also used widely in graphics acceleration chip solutions.

MBGA (Metal Ball Grid Array):

In this packaging type, the metal ceramic substrates are used for better durability and thermal performance. The chip is face-down, and the circuits are formed using a sputtering coating process. The electrical connection in MBGA is made by wire bonding. The excellent heat dissipation property makes it highly used in the power electronics, automotive systems, as well as in the high power computing applications.

Micro BGA Package:

A Micro Ball Grid Array (µBGA) is the most advanced surface mount packaging technology that is popular among PCB designers. Standard BGA packages use a ball pitch of 0.8 mm to 1.0 mm, while μBGA has a very fine pitch of 0.4 mm or less. Due to its compact design, it occupies a very small space and is therefore suitable for applications where smaller package size is vital.

Key Benefits of BGA Packaging

Although BGA packages offer advantages, there are also challenges involved when using them:

- Smaller footprint:The array of solder balls underneath components in BGA packages creates a smaller footprint while reducing PCB space requirement.

- Higher pin count:BGAs accommodate more input/output connections without increasing package size, thus allowing designers to add more functionality to minimal spaces.

- Improved electrical performance: The uniform and direct solder connections enhance electrical performanceand signal integrity due to the lower resistance and inductance.

- Better thermal dissipation: The solder balls touching the PCB directly facilitates heat transfer that minimizes overheating situations.

Major Challenges of Using BGA Packages

Despite their advantages, they come with several challenges during usage:

- Inspection difficulties: Hidden solder joints under the package cannot be visually inspected, X-ray inspection must be used.

- Rework challenges: When doing BGA rework, it has higher requirements on equipment, which require precise thermal control and special machines.

- Manufacturing complexity:To ensure proper solder joints, well-design PCB layout, controlled solder paste depositions, and a well managed reflow solder process are necessary.

Conclusion

Modern electronics depend on BGA packaging technology from everyday consumer products to the high performance computing systems. Different BGA types come with their advantages and disadvantages, so one has to select the right package and an experienced manufacturer. We’ve had years of experience and strict quality control processes at UnityPCB that combine with advanced equipment to offer reliable BGA assembly for all package types. Get in touch with us to discuss your project now!