Precision BGA Assembly Services for Cutting-Edge Electronics at UnityPCB

UnityPCB offers cutting-edge Ball Grid Array (BGA) assembly services for advanced electronic applications. Our team is highly skilled and experienced, we use top level equipment for component placement, soldering connections and thorough quality inspection. We deliver high-quality BGA assembly service that is crafted to your requirements, so that your products can achieve the maximum performance and durability.

| BGA Types: | µBGA, CTBGA, CABGA, CVBGA, VFBGA, LGA,etc |

| Minimum Pitch : | 0.4 mm |

| Maximum BGA Size: | 55 x 55 mm |

| Number of I/Os: | Up to 2500Package |

| Thermal Profiling : | Advanced Thermocouple Systems |

| Passive Footprints: | 0201, 01005, POP, 0603, and 0402 |

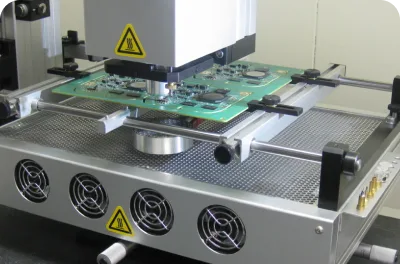

| Rework Stations: | Latest Model Hot-Air Rework Systems |

| Quality Standards: | ISO 9001 and IPC-A-610 standards |

Place solder paste precisely on the circuit board pads using a stencil printer to yield the best results.

The BGA component is then further placed accurately on the board with the help of superior automated placement equipment.

Component are heated in a controlled oven, which causes the solder to melt so as to create secure electrical connections.

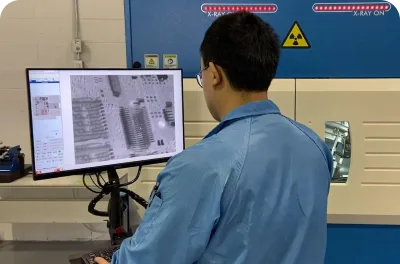

This is followed by cooling of the assembly after which the assembly is inspected and tested (often using X-ray)

Using specialized BGA rework techniques to solve any problem that might have been identified during the inspection process.

We adopt modern BGA assembly machines in our operations in order to guarantee quality and accuracy on every single project we handle.

In order to ensure zero defects in BGA assemblies, we follow strict quality control principles such as X-ray inspection and thermal profiling.

Our workers who operate in BGA assembly are highly trained and are experienced in handling tricky projects.

Together with customers, we tailor BGA assembly solutions so that they meet certain project needs and standards within the industry.

Consumer Electronics

Industrial Automation

Medical Devices

Telecommunications

IoT

BGA (Ball Grid Array) assembly entails soldering BGA packages that have solder balls at the underside to a PCB. This method gives a higher density connection and construct performance as compared to the earlier method of connection.

The advantages of BGA include a higher number of connections, better electrical characteristics, and improved thermal management compared to conventional leaded packages.

For BGA assemblies we ensure alignment, and soldering through the uses of x-ray inspection, thermal profiling, and advanced rework stations.

Yes, we have specialized rework stations and competent staff who can re-work BGA components when needed.

UnityPCB can handle a wide range of BGA packages, including Micro BGA, PBGA (Plastic BGA), CBGA (Ceramic BGA), and TBGA (Tape BGA).

Yes, UnityPCB has advanced technology and a qualified team to enable it to handle even the most complex BGA assemblies.

Contact Us