Metal PCB is a special circuit board designed to solve thermal management problems, and the most popular one is aluminum PCB. Aluminum PCB is widely used in various fields due to its excellent thermal management performance. In this blog, we will deeply explore the basic structure, manufacturing challenges, main advantages, and practical applications of aluminum PCB to help you fully understand aluminum PCB.

What Is an Aluminum PCB?

Aluminum PCB, also known as metal core PCB or aluminum-based PCB. Aluminum PCB uses aluminum substrates with excellent thermal conductivity as core materials, with an insulating layer and a copper foil conductive layer covering it. It is especially well-suited for applications requiring effective heat dissipation like LED lighting, due to its exceptional heat dissipation properties.

The Basic Structure of Aluminum Circuit Board

Copper Foil Layer: It’s located on the top of the circuit board. A preset circuit pattern is etched into the copper layer to connect and mount different electronic components. The copper foil thickness used in aluminum PCB is usually between 1 and 10 ounces.

Dielectric Insulation Layer: It is located between the copper layer and the aluminum base layer and is typically between 50 and 200 microns thick. This layer has three key functions: providing electrical insulation, achieving interlayer bonding, and conducting heat and dissipating heat.

Aluminum Substrate Layer: This layer is fabricated from aluminum material with high thermal conductivity. It helps to keep the device within the optimal operating temperature range by effectively conducting and dissipating the heat generated from the electronic components to the ambient environment. This layer also provides excellent mechanical strength and structural support. In addition, the aluminum substrate is suitable for conventional mechanical processing like drilling, stamping, cutting, etc.

Aluminum Base Membrane Layer: It is a selected and protected film laying on the aluminum substrate surface. The main function of this layer is to avoid surface scratches, oxidation, and etching. There are two kinds of aluminum-based film layers. One with a temperature resistance of 120°C and another up to 250°C.

Challenges in Aluminum PCB Manufacturing

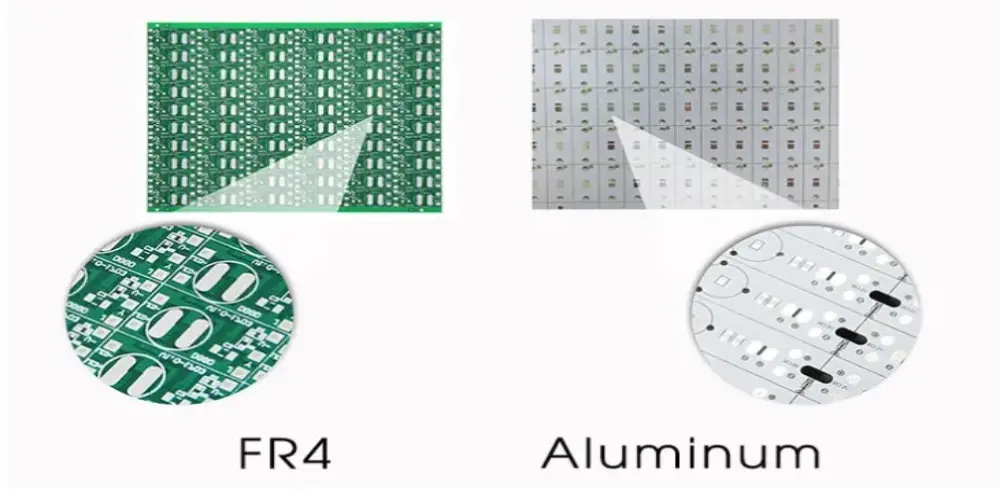

In fact, much of the manufacturing process for the aluminum PCB resembles the traditional FR4 PCB. However, it contains unique difficulties in its manufacturing process. The challenges or solutions normally encountered with its manufacturing process will be discussed here.

Precise Control of Copper Etching

The copper foil thickness of aluminum PCBs is generally thicker to ensure it can carry more current. The copper thickness is usually 3 oz or higher, which makes the etching process more complicated. Etching may cause the copper traces to be wider than expected.

Here are the solutions:

- To ensure that the trace width is maintained within the allowable tolerance range after etching, accurate line width compensation calculations need to be performed during the design phase.

- Etching factors and reagent parameters need to be strictly controlled during the production process.

Solder Mask Printing Issues

Using thicker copper foil results in a noticeable height difference between the trace surface and the substrate. This makes it difficult for the solder mask to adhere evenly.

Here are the solutions:

- Manufacturers usually adopt the double solder mask printing method and use high-quality solder mask oil.

- Resin filling is sometimes done prior to solder mask printing in order to guarantee the solder mask’s dependability and quality.

Mechanical Manufacturing

The most common key steps in the mechanical manufacturing process of an aluminum PCB usually include drilling, forming, V-shaped notches, and vias. Drilling may leave burrs inside that will affect electrical performance.

Here are the solutions:

- Small Batch Production:Professional milling cutters and electric milling can be used. This approach provides greater flexibility in processing accuracy and processing speed.

- Large-Scale Production: Precise control of the mold-forming process is required to ensure uniform quality and minimize defects.

- Thick Copper Aluminum PCB:Special adjustment of drilling parameters is also required to avoid burrs formation and ensure high-quality

How to Store Aluminum-Based PCB?

The storage environment for aluminum PCBs must meet strict specifications. Due to its moisture-prone nature, it is easy to turn yellow and black once it comes into contact with moisture, affecting the appearance of the product. A dry, light-proof environment should be selected when storing aluminum PCBs. The circuit boards need to be vacuum packed, and once the vacuum package is opened, they must be used within 48 hours.

Classification of Aluminum PCBs by Dielectric Materials

It can be divided into the following three categories according to the material of the dielectric layer and the performance of the PCB.

Universal Aluminum PCB

Epoxy glass fiber prepreg is commonly used to create the dielectric layer. The aluminum PCB is widely used in electronic products without extreme power demand but with excellent heat dissipation performance.

High Thermal-conductive Aluminum PCB

Epoxy resin is typically used to make the dielectric layer. The resin used needs to have high thermal conductivity to ensure good heat transfer performance.

High-frequency Aluminum PCB

The dielectric layer is usually made of polyimide resin glass fiber prepreg or polyolefin. These materials have excellent electrical properties, especially low Df (dielectric loss) and low Dk (dielectric constant). It can effectively support the transmission of high-frequency signals and reduce signal attenuation and electromagnetic interference.

The Key Benefits of Aluminum Circuit Board

We list a few advantages of aluminum circuit boards in this section. You can discover the reasons that led you to select this circuit board.

Green Manufacturing

Aluminum is a non-toxic material that is also fully recyclable and its manufacturing process also has a relatively low impact on the environment. The easy assembly characteristics of aluminum PCBs also help to reduce the energy consumption of the production process.

Excellent Thermal Management

The heat dissipation performance of aluminum PCB is higher than FR4 PCB. Aluminum PCB can transfer heat away from vital components, which can effectively protect them from high-temperature damage. Due to its excellent thermal management capabilities, there are no serious expansion or contraction issues.

High Durability

Aluminum substrates have better mechanical strength, toughness, and durability than ceramic or fiberglass substrates. This also effectively reduces the risk of accidental damage during manufacturing, transportation handling, and daily use.

Lightweight Options

Compared to traditional FR4 PCB, aluminum PCB is lighter. The lightweight properties are particularly suitable for areas like aerospace or portable electronic devices where weight is strictly required.

What Are the Applications of Aluminum PCBs?

Due to the good heat dissipation performance and durability of aluminum-based PCBs, they have taken a very important place in modern electronic products, especially in those with quite high demands on thermal management. Here we give some examples.

Lighting: Commercial lighting, LED Display, Automotive lighting, Home lighting,

Audio equipment: Power amplifiers, Audio processors, High power sound systems

Computers: CPU cooling system, Graphics card, Power management circuit

Power Modules: Inverter, Converter

Automotive: Battery management system, Motor drive, Air conditioning system

Aluminum PCB vs. FR4 PCB: A Comprehensive Comparison

You may see that FR4 PCB is used in most applications. Now we compare FR4 and aluminum PCB in some aspects, you can know aluminum PCB deeply.

| Aspect | Aluminum PCB | FR4 PCB |

| Substrate Materials | Aluminum core | Glass fiber-reinforced epoxy resin |

| Mechanical Strength | Higher mechanical strength and toughness, resistant to mechanical stress | Moderate, can be brittle under stress |

| Thermal Conductivity | High thermal conductivity makes heat dissipation effective | Low thermal conductivity, requires additional thermal management solutions |

| Coefficient of Thermal Expansion | Low, reducing thermal stress on components | Higher, leading to potential thermal expansion mismatch with components |

| Electrical Insulation | Requires special insulation coatings | High electrical insulation due to epoxy resin |

| Cost Consideration | Higher cost due to material and processing complexity | Lower cost, suitable for cost-sensitive applications |

| Application | Ideal for heat-sensitive applications | Suitable for general-purpose electronics |

UnityPCB: Your Reliable Aluminum PCB Manufacturer

With nearly 20 years of experience in PCB manufacturing, UnityPCB provides one-stop services including PCB design, component sourcing, manufacturing, assembly, quality control, etc. We have a factory covering an area of approximately 12,400 square meters, with 5 SMT and 3 THT production lines installed, equipped with advanced machines. UnityPCB is committed to providing high-quality PCB and PCBA with fast turnaround times, fully compliant with ISO standards. Looking for a reliable aluminum PCB manufacturer? Contact UnityPCB today for a quote and professional support.